cnrservices

Member

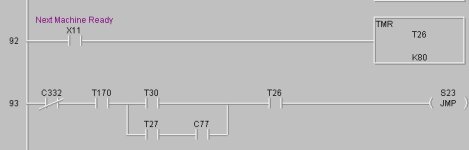

Attached is a Directsoft file for a machine that watches the next machine upline for a ready signal, and if the signal (X11) is there it sends product through.

However this machine in particular does not stop when the X11 signal drops, it "preps" itself by grabbing one last piece & continuing through until it is ready to drop on the conveyor. At this time it is usually holding a piece just above the last piece on the stopped conveyor. As soon as the ready X11 goes true, the machine drops the readied piece on top of the other piece & this causes a problem every time the line is resarted.

I tried adding a rung & having X11 start a 8 Second timer, then using the timer in place of the X11 instruction in Line 90, accepted the edits OK, wrote to the PLC, but at the end of the download where the PLC stops RUN mode & shows PAUSED, the communication with the PLC halted, the CPU Fault light on the PLC came on & I got a error message about the processor memory. I had to power down the PLC & it came back up in RUN mode OK. I also had to shut down Directsoft & DSLaunch & restart them to restart the 240 COMM link.

I went online & redownloded the original file, and the machine ran as before. This happenned a 2nd time exactly the same, so figuring a CPU problem replaced the DL240 with a brand new CPU, downloaded the original file & tried to edit it. SAME CRASH

Now I successfully did the exact same edit (see lines 204 - 206.)

Is there any reason one stage of a program won't take a verified edit, but another stage will?

Also, am I going about this the right way - I want to wait 8 seconds after the Ready signal goes true before dropping a part.

Hopefully some A-D "specialists" can give this AB programmer some guidance.

However this machine in particular does not stop when the X11 signal drops, it "preps" itself by grabbing one last piece & continuing through until it is ready to drop on the conveyor. At this time it is usually holding a piece just above the last piece on the stopped conveyor. As soon as the ready X11 goes true, the machine drops the readied piece on top of the other piece & this causes a problem every time the line is resarted.

I tried adding a rung & having X11 start a 8 Second timer, then using the timer in place of the X11 instruction in Line 90, accepted the edits OK, wrote to the PLC, but at the end of the download where the PLC stops RUN mode & shows PAUSED, the communication with the PLC halted, the CPU Fault light on the PLC came on & I got a error message about the processor memory. I had to power down the PLC & it came back up in RUN mode OK. I also had to shut down Directsoft & DSLaunch & restart them to restart the 240 COMM link.

I went online & redownloded the original file, and the machine ran as before. This happenned a 2nd time exactly the same, so figuring a CPU problem replaced the DL240 with a brand new CPU, downloaded the original file & tried to edit it. SAME CRASH

Now I successfully did the exact same edit (see lines 204 - 206.)

Is there any reason one stage of a program won't take a verified edit, but another stage will?

Also, am I going about this the right way - I want to wait 8 seconds after the Ready signal goes true before dropping a part.

Hopefully some A-D "specialists" can give this AB programmer some guidance.

Last edited: