Terry Woods

Member

- Join Date

- Apr 2002

- Posts

- 3,170

Well... let's see what you can come up with...

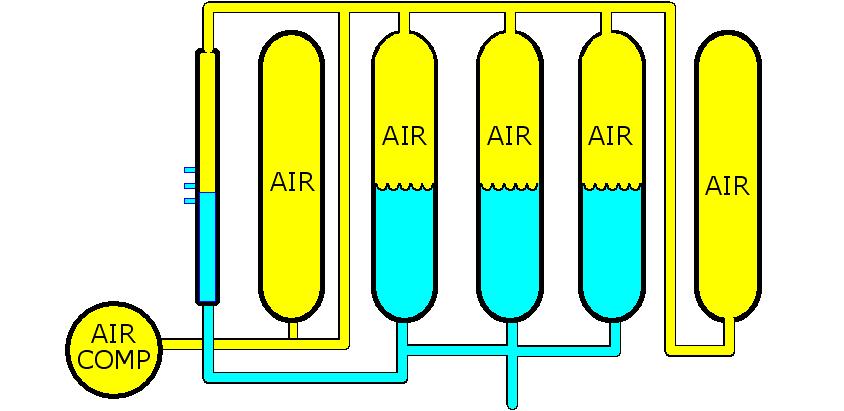

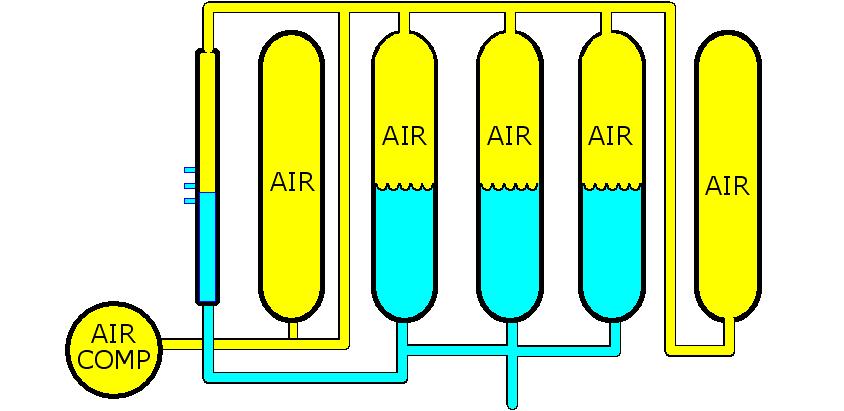

We have a hydraulic press. The hydraulic pressures contained in two accumulator systems close the press. The first accumulator provides low pressure (approx 500-psi) and the second accumulator provides high pressure (approx 5000-psi, approx 150F). The low-pressure accumulator provides approximately 95% of the closing. The high-pressure accumulator provides the last 5% of closing.

It is, of course, very important that the accumulators have the correct amount of water (water mixed with oil) when the accumulators charge to their "set-point pressure". This is easily determined in the low-pressure system by means of a set of float-switches.

Last week, we had a severe air leak. (Apparently, a smaller leak had been there for quite a while.) It was a few hours before the night crew identified the problem and got it isolated. In the meantime, all five bottles filled with water.

When they completed the repairs, they tried a cycle. When the high-pressure phase of the cycle began, the pressure dropped from 4500 psi to 1200 psi... in about... one second. A normal 30-second close took about 5-minutes. A normal cycle-time is five-minutes.

So... here is my problem. I need to be able to monitor the water level in the high-pressure system. At this time, the only means we have to judge the water level is by means of a set of three petcocks mounted on a tube. The tube is mounted in parallel with the airside and the waterside of the high-pressure accumulator. Of the three petcocks, the center petcock is at the required level. The other petcocks are mounted 2-inches above and below the center petcock. It is easy to determine the level of the water as long as the water is where it should be (+/- 2").

Here is a diagram of the High Pressure Accumulator System.

The problem is that once the water level moves out of that range it is impossible to know the trend. Once it is determined that the level is not where it should be, actions are taken to try to restore the water to the proper level (either add air or add water). Adding water is the easier task. Adding air, on the other hand, is a long process. While adding air, however, we do not know if we are gaining ground or losing ground. That is, once the water level is above the top petcock, it is impossible to know, on a cycle to cycle basis, whether the "at pressure" water level is increasing or decreasing.

The same issue (to a lesser degree) applies when the water level is below the bottom pet-****.

I would really like to use a 4-20mA sensor to provide continuous level information.

We have a hydraulic press. The hydraulic pressures contained in two accumulator systems close the press. The first accumulator provides low pressure (approx 500-psi) and the second accumulator provides high pressure (approx 5000-psi, approx 150F). The low-pressure accumulator provides approximately 95% of the closing. The high-pressure accumulator provides the last 5% of closing.

It is, of course, very important that the accumulators have the correct amount of water (water mixed with oil) when the accumulators charge to their "set-point pressure". This is easily determined in the low-pressure system by means of a set of float-switches.

Last week, we had a severe air leak. (Apparently, a smaller leak had been there for quite a while.) It was a few hours before the night crew identified the problem and got it isolated. In the meantime, all five bottles filled with water.

When they completed the repairs, they tried a cycle. When the high-pressure phase of the cycle began, the pressure dropped from 4500 psi to 1200 psi... in about... one second. A normal 30-second close took about 5-minutes. A normal cycle-time is five-minutes.

So... here is my problem. I need to be able to monitor the water level in the high-pressure system. At this time, the only means we have to judge the water level is by means of a set of three petcocks mounted on a tube. The tube is mounted in parallel with the airside and the waterside of the high-pressure accumulator. Of the three petcocks, the center petcock is at the required level. The other petcocks are mounted 2-inches above and below the center petcock. It is easy to determine the level of the water as long as the water is where it should be (+/- 2").

Here is a diagram of the High Pressure Accumulator System.

The problem is that once the water level moves out of that range it is impossible to know the trend. Once it is determined that the level is not where it should be, actions are taken to try to restore the water to the proper level (either add air or add water). Adding water is the easier task. Adding air, on the other hand, is a long process. While adding air, however, we do not know if we are gaining ground or losing ground. That is, once the water level is above the top petcock, it is impossible to know, on a cycle to cycle basis, whether the "at pressure" water level is increasing or decreasing.

The same issue (to a lesser degree) applies when the water level is below the bottom pet-****.

I would really like to use a 4-20mA sensor to provide continuous level information.