On systems like this, it's worthwhile to take some time each morning to sing your own version of "Lord, Won't You Buy Me Some POINT I/O", which I think was originally written by Woody Guthrie.

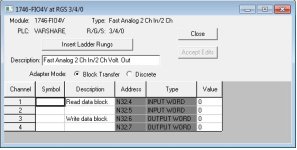

The good news is that these SLC-500 Analog modules were built in the era where SLC data table memory was precious, so they aren't very complicated.

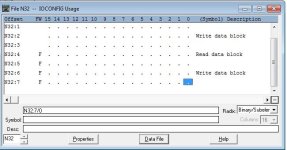

There is no "configuration" file you need to send to the module, only those two words of Output data.

Get the User Manual:

https://literature.rockwellautomation.com/idc/groups/literature/documents/um/1746-um009_-en-p.pdf

The physical setup is simple; all you have is some onboard DIP switches to configure the Inputs for voltage or current mode. The Outputs are both Voltage mode (FIO4

V) on this module; you need an FIO4

I for Current mode outputs.

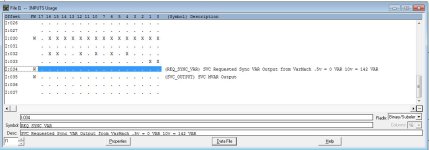

The scaling is the only hard part.

The user manual does a pretty good job of showing you the millvolts or milliamts per integer count and that the first couple of bits of the data word for the Output are unused; see the diagrams on Pages 32-35.

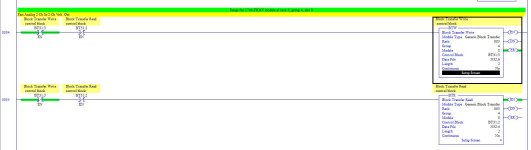

For the Input, you can just run a repeating BTR instruction and scale the value as appropriate in your ControlLogix program.

Page 33 of the user manual shows you the resolution for different Analog Input ranges. The module is only capable of 12 bit resolution (0-4095) at best.