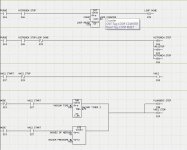

I was given a small PLC project from my dad for his company and I have ran into a few problems. I have found it necessary to use an output in my program more than once, so I made up subroutines to accomodate for that seeing as I cannot do it in the main program. But my main concern is when I download the program to the PLC, it does nothing. Absolutely nothing. I'll be the first one to say I have no experience other than in school and that was 2 years ago and even then my teacher walked us through the programs.

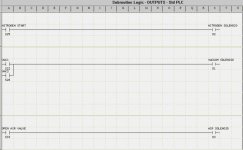

I've attached the program and a sequence chart that I made up. I have tried to troubleshoot this for a couple days now and I just KNOW its going to be something quite simple but yet something that I am unable to find because I lack the knowledge. I would greatly appreciate any help, and if I have broken any rules by all means remove this post.

Thanks in advance

I've attached the program and a sequence chart that I made up. I have tried to troubleshoot this for a couple days now and I just KNOW its going to be something quite simple but yet something that I am unable to find because I lack the knowledge. I would greatly appreciate any help, and if I have broken any rules by all means remove this post.

Thanks in advance