MightyMoose

Member

Hello everyone, I have yet another thread about PID's coming your way.

Any PLC5 users in the house?

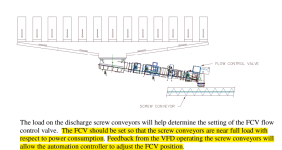

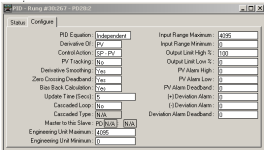

I'm currently writing a program and have little experience with PIDs. I'm attempting to use the feedback from 2 VFDs controlling screw conveyors to adjust the position of a Flow Control Valve.

The goal is to keep the VFDs running at near full power consumption. I think my process variable should be the kW% and the CV is the position of the FCV.

I think I've been staring at the problem for so long that it feels impossible.

If anyone can give me a little guidance or if I'm simply over thinking this because I only have a little knowledge of PIDs.

Any PLC5 users in the house?

I'm currently writing a program and have little experience with PIDs. I'm attempting to use the feedback from 2 VFDs controlling screw conveyors to adjust the position of a Flow Control Valve.

The goal is to keep the VFDs running at near full power consumption. I think my process variable should be the kW% and the CV is the position of the FCV.

I think I've been staring at the problem for so long that it feels impossible.

If anyone can give me a little guidance or if I'm simply over thinking this because I only have a little knowledge of PIDs.