stayclashy80

Member

Hello everyone,

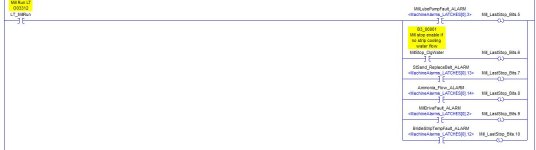

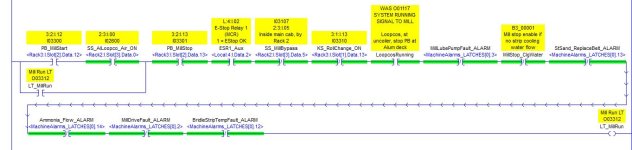

So I need help setting up traps in Studio 5000. Disclaimer I'm an intermediate PLC programmer so I need lots of help and I need to learn a lot. My initial plan was just to use a one shot based on conveyor running status bit and then a bunch of MOV instructions to send data to newly created storage tags. Problem was I needed bit data not word data and I couldn't use bit data for the MOV instruction. I looked around and found OSR instruction ( one shot rising ) and it said it has a storage bit. I tried this and got scared because the conveyors started having transients so I removed the code. So now I need to know if the OSR actually changes the value of bits or not. I noticed in cross reference it was referenced as "destructive" type. I'm not sure what that means either. Any help would be greatly appreciated.I attached a screen shot of the logic I had in temporarily. Thanks so much. You guys are awesome and always help me out so much.

So I need help setting up traps in Studio 5000. Disclaimer I'm an intermediate PLC programmer so I need lots of help and I need to learn a lot. My initial plan was just to use a one shot based on conveyor running status bit and then a bunch of MOV instructions to send data to newly created storage tags. Problem was I needed bit data not word data and I couldn't use bit data for the MOV instruction. I looked around and found OSR instruction ( one shot rising ) and it said it has a storage bit. I tried this and got scared because the conveyors started having transients so I removed the code. So now I need to know if the OSR actually changes the value of bits or not. I noticed in cross reference it was referenced as "destructive" type. I'm not sure what that means either. Any help would be greatly appreciated.I attached a screen shot of the logic I had in temporarily. Thanks so much. You guys are awesome and always help me out so much.