Tachometer to Siemens PLC input

- Thread starter KatSpike

- Start date

Similar Topics

I've been asked to add a speed readout to an existing machine, 1200 RPM.

Is there an easier way than cutting a hole in a small box, installing a...

Good Morning ,

Do you guys know of any tachometers ( 4-20 ma ) with a fragile soft wheel to sense FPM on a cloth belt ? I was thinking of...

Hello guys i wish if you could help me out with your experience.

I must install a PLC on the diesel driven machine and PLC must measure the the...

Is it possible to take a tachometer signal to a plc and use the plc to transfer the signal to a remote location?

I work at a paving company and...

hi guys ,

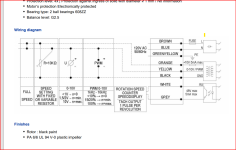

im trying to get a rpm reading off a shaft of a low rpm rotor, the roter speed is well less than 200 rpm ,

how would i go about this...