drbitboy

Lifetime Supporting Member

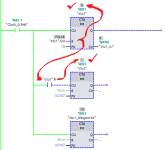

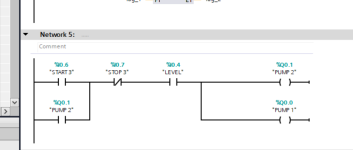

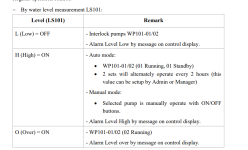

One more interpretation of @Puddle's idea: if we leave ctu1.QU on the R pin of ctu1, as when we started, then that will drive the bit ctu1.R, which becomes 1 for a single scan cycle at each first stage (ctu1) reset, and so could be used as the trigger for the cascaded secondary ctu1. This works, and might be the most easily understood six months from now:

Last edited: