Ganeshjangam

Member

hello,

i am using compact logix L16ER PLC and emerson Micro motion 5700 MFM.

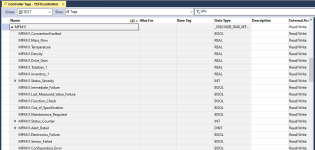

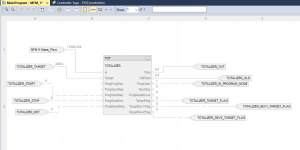

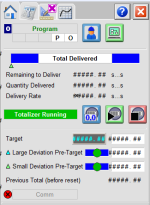

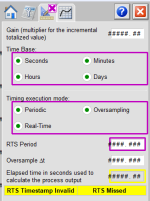

i used TOTALIZER block in studio 5000 to calculate transferred quantity.

i am facing issue to calculate accurate transfered quantity.

MFM gives flow rate of air....so how can i calculate actual product flow rate so that i get exact quantity.

MFM gives data of flow rate,density,gain and temperature...how to use this all parameters to knw actual flow rate of product.

thanks in advance

i am using compact logix L16ER PLC and emerson Micro motion 5700 MFM.

i used TOTALIZER block in studio 5000 to calculate transferred quantity.

i am facing issue to calculate accurate transfered quantity.

MFM gives flow rate of air....so how can i calculate actual product flow rate so that i get exact quantity.

MFM gives data of flow rate,density,gain and temperature...how to use this all parameters to knw actual flow rate of product.

thanks in advance