Hi, I need some help write a PLC instruction. I am using Proficy Machine Edition 6.5.

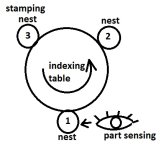

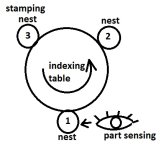

Our indexing rotating table has 3 nests that are equally apart. #1 nest is for part sensing. #2 nest does nothing. #3 nest is for stamping.

If the part is detected, I want to activate the stamp. I want the shift to occur when the index motor is activated (Index_on). I want to assign 1 to a shifting register to indicate that the part is present (Part_present).

I am not familiar with any bit-shift instruction. if you could show a screenshot, that would be very helpful. Or just tell me what instruction I should use and what parameters should I use the Inex_on & Part_present.

Thank you.

Our indexing rotating table has 3 nests that are equally apart. #1 nest is for part sensing. #2 nest does nothing. #3 nest is for stamping.

If the part is detected, I want to activate the stamp. I want the shift to occur when the index motor is activated (Index_on). I want to assign 1 to a shifting register to indicate that the part is present (Part_present).

I am not familiar with any bit-shift instruction. if you could show a screenshot, that would be very helpful. Or just tell me what instruction I should use and what parameters should I use the Inex_on & Part_present.

Thank you.