Rbelshee

Member

Hello All,

As you can guess by the title I am a total noob to programming PLC's. So my problem is that I have an old Pallet wrapper that uses an Allen Bradley SLC 500 1747-l20A PLC. I have spent 6 months working with the manufacturer of the pallet wrapper but still can not get a proper program loaded on the EPROM chip and loaded to the PLC (it always shows PLC fault)

At this point I have purchased 3 more PLC's and a new CPU chip... it has to be a software issue since I can use a EPROM chip off a different machine and the PLC does not show CPU fault.

I reached out to Allen Bradley and found that this PLC is very old and a legacy non supported piece of hardware. Between cables and software I am looking at over a grand to make this work.

I am looking at EZ-Automations PLC and their EZ-PLC editor software, it seems much more straightforward.

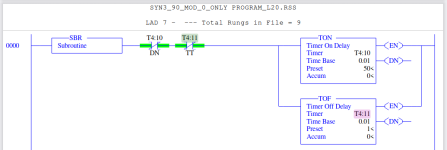

SO the problem is that I have the ladder logic and .RSS file from the old PLC but need to convert it to work with EZ plc. Remember line one of this thread... I am not familiar with ladder logic.

I am curious if anyone out there is willing to help me out (willing to pay a little) and convert the ladder logic over to EZ-PLC. I don't want to have to learn the old RS Logix system and the EZ PLC just to convert it. I do have the file, a PDF of the ladder logic and a wiring diagram of the machine.

I know this is a long shot, so thanks in advance.

P.S. as I mentioned I do have 3 nice plc's if you want one... maybe trade for services??? plus cash???

As you can guess by the title I am a total noob to programming PLC's. So my problem is that I have an old Pallet wrapper that uses an Allen Bradley SLC 500 1747-l20A PLC. I have spent 6 months working with the manufacturer of the pallet wrapper but still can not get a proper program loaded on the EPROM chip and loaded to the PLC (it always shows PLC fault)

At this point I have purchased 3 more PLC's and a new CPU chip... it has to be a software issue since I can use a EPROM chip off a different machine and the PLC does not show CPU fault.

I reached out to Allen Bradley and found that this PLC is very old and a legacy non supported piece of hardware. Between cables and software I am looking at over a grand to make this work.

I am looking at EZ-Automations PLC and their EZ-PLC editor software, it seems much more straightforward.

SO the problem is that I have the ladder logic and .RSS file from the old PLC but need to convert it to work with EZ plc. Remember line one of this thread... I am not familiar with ladder logic.

I am curious if anyone out there is willing to help me out (willing to pay a little) and convert the ladder logic over to EZ-PLC. I don't want to have to learn the old RS Logix system and the EZ PLC just to convert it. I do have the file, a PDF of the ladder logic and a wiring diagram of the machine.

I know this is a long shot, so thanks in advance.

P.S. as I mentioned I do have 3 nice plc's if you want one... maybe trade for services??? plus cash???