According this

https://www.tunasistem.com.tr/image/kullanim/tuna-ltr.pdf

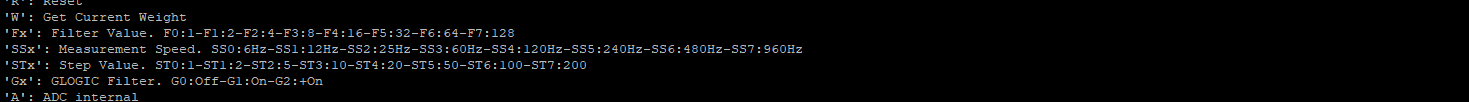

For default TUNA have 115200,8,N,1 port configuration (Hyperterminal screenshot).

I hate it when speed settings aren't writed clearly anywhere on manuals.

USB connection also looks like that it is simulating serial port to TUNA.

Some devices have serial pins at paraller with USB com port. If that is case then USB connection is taking all communications from device.

If you don't see RX led blinking, take USB cable off from TUNA and check again if RX led start blinking.

https://www.tunasistem.com.tr/image/kullanim/tuna-ltr.pdf

For default TUNA have 115200,8,N,1 port configuration (Hyperterminal screenshot).

I hate it when speed settings aren't writed clearly anywhere on manuals.

USB connection also looks like that it is simulating serial port to TUNA.

Some devices have serial pins at paraller with USB com port. If that is case then USB connection is taking all communications from device.

If you don't see RX led blinking, take USB cable off from TUNA and check again if RX led start blinking.