drbitboy

Lifetime Supporting Member

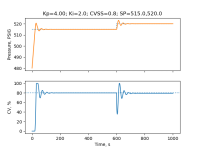

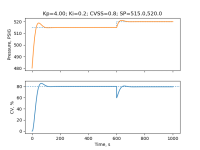

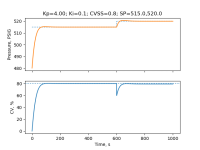

@Ones_Zeros: what is the highest CV you have seen in stable (i.e. not startup) operation? If it's less than 70%, then clamp the PID CV output to 10% or so above that value, and make sure the PID implements some form of anti-windup on the reset (integral term).

E.g. if the maximum stable value is 40%, clamp the PID CV output to 45%. This may require scaling the controller gain, depending on the PID implementation.

E.g. if the maximum stable value is 40%, clamp the PID CV output to 45%. This may require scaling the controller gain, depending on the PID implementation.