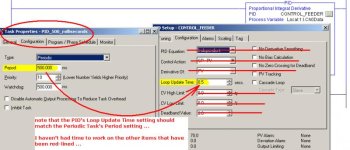

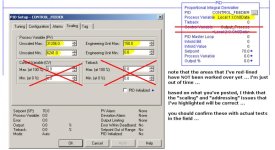

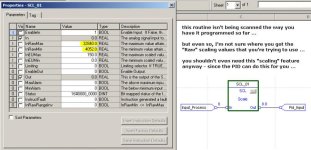

Set in RSLogix 5000 pid

- Thread starter frank222

- Start date

Similar Topics

Processor: 1769-L30ER; Logix 5000: v32.02

I have an AOI that's been used in previous applications without issue, and have added a TON...

I have a question on a subject of etherent nodes in rslogix 5000 project tree for a project that I am working on. I am trying to read if read...

for some reason when i try to change the value for the preset on a rto timer after i change it accept changes it goes back to the old value, any...

Hello Everybody..

I am attempting to get online with our PLC via the Ethernet/IP card that is tied into our Wonderware 14 port managed switch...

To All,

Please help,

I am new to Rockwell automation and normally use Siemens, I am trying to finish up a program and now need to use a "Heart...