Ryan_Flowers

Lifetime Supporting Member

Hello,

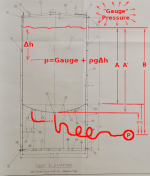

I am trying to make sense of an incorrect reading or how to calibrate one of our liquid tanks.

Volume of the Soy Oil tank = approx. 8078 gallons US or rounded to nearest whole number in lbs = 60,000(1 gal water = 8.34 lbs and specific gravity of soy oil approx. = 0.92 7.672 x 8078 = 61,980 lbs)

If my math there is correct my 100% of the scale should be 60,000 lbs in the process.

Digital readout P/N: imp20160, Link to manual

Pressure transmitter P/N: px41t1-010gi Link to manual. This transmitter is a 0-10 PSIG range

Again, the problem is that going off a balance sheet, our readout currently in place is wrong. I am trying to calibrate it and prove whether the value is correct or not. So I follow the red lion manual section Module 2 to set the scale manually like the following. I set the 0% = 0, inp 1 = 4.00, 100% = 60,000, and inp 2 = 20.00 . However I am still off by about 14,000 lbs. What if anything does someone see that I am doing wrong here? Is there a better transmitter to readout combo from another manufacturer?

Thanks for all the help in advance.

I am trying to make sense of an incorrect reading or how to calibrate one of our liquid tanks.

Volume of the Soy Oil tank = approx. 8078 gallons US or rounded to nearest whole number in lbs = 60,000(1 gal water = 8.34 lbs and specific gravity of soy oil approx. = 0.92 7.672 x 8078 = 61,980 lbs)

If my math there is correct my 100% of the scale should be 60,000 lbs in the process.

Digital readout P/N: imp20160, Link to manual

Pressure transmitter P/N: px41t1-010gi Link to manual. This transmitter is a 0-10 PSIG range

Again, the problem is that going off a balance sheet, our readout currently in place is wrong. I am trying to calibrate it and prove whether the value is correct or not. So I follow the red lion manual section Module 2 to set the scale manually like the following. I set the 0% = 0, inp 1 = 4.00, 100% = 60,000, and inp 2 = 20.00 . However I am still off by about 14,000 lbs. What if anything does someone see that I am doing wrong here? Is there a better transmitter to readout combo from another manufacturer?

Thanks for all the help in advance.