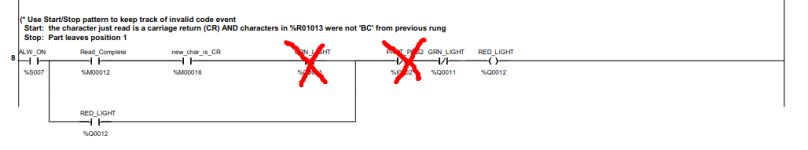

I still do not think the read loop is robust as it is implemented now; relying on reading exactly 29 characters will eventually fail and hang up the process.

This is correct.

1. As of now, When i scan a good code, it does as expected.

2. When i scan a correct length bad code, the red light illuminates.

If i scan a good code after (without breaking PART_POS1) red and green illuminate and the cyl retracts.

(this is alright, but should switch from red to green, not both)

3. When an incorrect, mismatch length barcode scans, it does nothing, Then a good code scanned does nothing. (light should illuminate red)

Then if i break contact with PART_POS1, make and rescan, it does as expected.

So as of now, the logic cannot robustly verify good and bad codes.

What's next? I have this almost wrapped, this last bit and i believe im set. I am going to build one more assembly to practice on and work at fully understand the logic we've come up with here

** IS this code from post #60 http://www.plctalk.net/qanda/showpost.php?p=895960&postcount=60

still possibly the way to get this more robust?

Last edited: