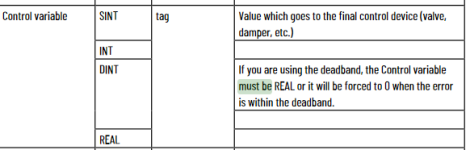

Hi I am trying to understand the best method of providing bumpless transfer to the PID function (not PIDE)

The existing code shows

In Manual Mode

Copy ProgCV to PID.SO . ProgCV is a value i am sending to the device by code

Copy ProgCV to OperCV

In Auto Mode

Copy the ProgSP to OperSP

Copy the CV to OperCV

However when the PID is set to auto it is dropping to 0 CV then the CV builds under the PID action

What is the preferred method of achieving bump less transfer from manual to auto mode change

Thanks

The existing code shows

In Manual Mode

Copy ProgCV to PID.SO . ProgCV is a value i am sending to the device by code

Copy ProgCV to OperCV

In Auto Mode

Copy the ProgSP to OperSP

Copy the CV to OperCV

However when the PID is set to auto it is dropping to 0 CV then the CV builds under the PID action

What is the preferred method of achieving bump less transfer from manual to auto mode change

Thanks