Hi all,

I am having trouble trying to stack Yesterday Totalizer.

I need to view three values in my HMI (Accumolative Totalizer, Today Totalizer, Yesterday Totalizer).

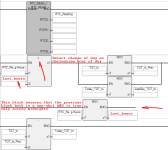

As you view in the image of PLC Ladder;

Previous accumolative totalizer start when each day ends at 0 hours 0 minutes 0 seconds.

Today Totalizer = Totalizer - Previous accumulative Totlaizer.

However, when I try to get yesterday's Totalizer it always goes to 0. Because, at the end of each day; today totalizer = 0.

How can I stack today's totalizer to yesterday's totalizer before it goes to 0.

Is there any way other than deducting 1 second for the operation.

Thanks in advance

I am having trouble trying to stack Yesterday Totalizer.

I need to view three values in my HMI (Accumolative Totalizer, Today Totalizer, Yesterday Totalizer).

As you view in the image of PLC Ladder;

Previous accumolative totalizer start when each day ends at 0 hours 0 minutes 0 seconds.

Today Totalizer = Totalizer - Previous accumulative Totlaizer.

However, when I try to get yesterday's Totalizer it always goes to 0. Because, at the end of each day; today totalizer = 0.

How can I stack today's totalizer to yesterday's totalizer before it goes to 0.

Is there any way other than deducting 1 second for the operation.

Thanks in advance