angadh

Member

Hi,

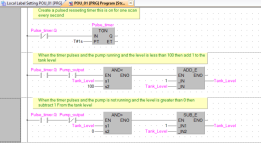

I have developed a small PLC program of few motors, PB, and a tank. The communication between HMI and PLC is Modbus TCP. While I was trying to develop the HMI simulation the tank level doesn't work, I tried adding a separate counter to increase the level of the tank. However, the level doesn't vary. Any advice on how to increase the level of the tank according to Motor-1 turned on and decreases when Pump-1 turns on. Could anyone suggest any plan to solve the issue. HMI used here is Advanced HMI and PLC is Click PLC.

I have developed a small PLC program of few motors, PB, and a tank. The communication between HMI and PLC is Modbus TCP. While I was trying to develop the HMI simulation the tank level doesn't work, I tried adding a separate counter to increase the level of the tank. However, the level doesn't vary. Any advice on how to increase the level of the tank according to Motor-1 turned on and decreases when Pump-1 turns on. Could anyone suggest any plan to solve the issue. HMI used here is Advanced HMI and PLC is Click PLC.