Thanks for that detail ! I realize how hard these things are when it's a continuous process system and can't be easily shut down. If there's an over-flowed buffer in PLC A or PLC C then maybe that will solve the issue.

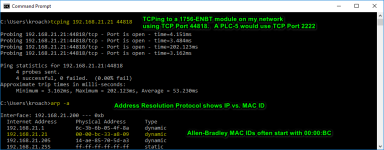

Using TCPING on each of the IP addresses should be a good indicator that the IPs are set correctly, but the architecture of your network might still mean that PLC A and C are not physically able to connect to one another.

Maybe it's just a coincidence that a download to PLC B happened when the comms was lost to those other controllers.

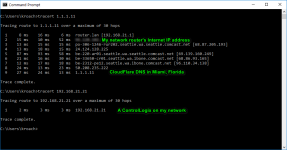

If you can, use this problem as an opportunity to map out the control network at his facility. If it has 20-year-old IP addresses that use actual public Internet server addresses, there are probably links and switches and devices you don't even know about.

I like to use Angry IP Scanner set up to look for various ports that are common in industrial automation:

80 HTTP for web servers

8080 HTTP alternate

22, 23 SSL

502 Modbus/TCP

503 Modbus/TCP alternate

2222 Allen Bradley CSPv4

44818 Allen Bradley EtherNet/IP

And I would use PING and TCPING and ARP -A and RSLogix to be sure I knew the actual MAC ID of each of those PLC-5 controllers.

A web browser, TCPing, and Angry IP Scanner are just simple free tools that most controls folks can use. They are only toys compared to heavy-duty network monitoring and management tools, which is why IT departments exist.

This morning I read a fascinating story that touches on the topic of public IP addresses:

https://www.washingtonpost.com/technology/2021/04/24/pentagon-internet-address-mystery/

In the early 1990s when IP addressing was very new, I used to field questions all the time where people had followed the user manual exactly and couldn't get their Ethernet messaging to work with PLC-5 and SLC-5/05 controllers. Often they had followed the directions too exactly, and had used an address "192.168.130.30", which was in the manual because the tech support lab was in room 130 on the first floor at Allen-Bradley in Mayfield Heights, so you could roll in equipment through the same loading dock as the cafeteria used.