Scaling a zero center pressure sensor

- Thread starter ssarora

- Start date

Similar Topics

Hi, I have a vacuum transmitter, it's range is 30 to 0 inches of mercury. My spec calls for inches of water, no problem, use SCP to scale 0-16733...

Hi, I have a ControlLogix system with 1756-IF16 analogue inputs. I can't scale the inputs at the card as there is a requirement to facilitate...

I know nothing about simaticnet OPC server. I do know Kepware. I would only ever scale raw to engineering in the PLC, but it is possible to scale...

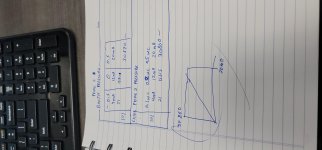

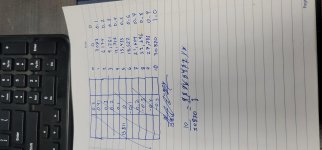

Hi all.

I'm working on a rehab and I'm trying to figure stuff out.

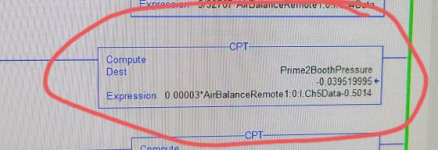

See screenshot at the bottom.

Local:5:I.Data[6] in BTD instruction is a...

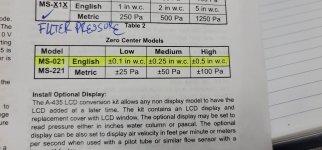

Hello all,

First post here. Hitting a wall with finding info on this topic online, and none of my coworkers have a clue.

I have a PanelView...