hi i have had a mind blank on a tia and was wondering for a easy option .

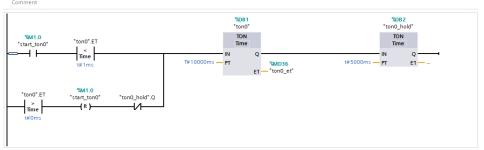

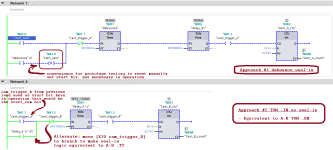

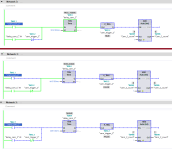

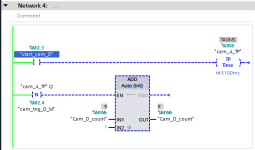

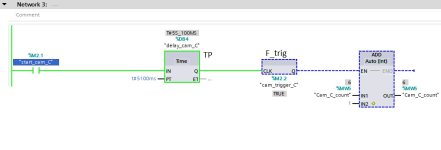

i have a trigger signal that will see a mark and set a delay timer off and then trigger a out put to trigger a vision camera ?

how do you hold the triger on to the timer if the timer loses its enable it stops?

in ab you could use a tt bit but not sure in Tia

silly question i know but im sure you guys have the answer

thank stu

i have a trigger signal that will see a mark and set a delay timer off and then trigger a out put to trigger a vision camera ?

how do you hold the triger on to the timer if the timer loses its enable it stops?

in ab you could use a tt bit but not sure in Tia

silly question i know but im sure you guys have the answer

thank stu