Ken Roach

Lifetime Supporting Member + Moderator

Thanks for those details ! Some simplified background highlights:

RIO and DH+ share the same signal and wiring but different protocols. The SLC-5/04 has a DH+ port built into the CPU, but can have a RIO Scanner module in any slot (more than one, up to a memory limit).

It's a "Manchester-encoded" signal, where the timing of the rising and falling edges makes a 1 or 0, not the signal level. The signal interface is remarkably tolerant of installation and noise problems, to the point where it really spoiled A-B users for less rugged but faster modern networking.

But time marches on, and the chips aren't economical to produce anymore, so A-B bought their last batch five or so years ago and demand will dictate future prices. Probably there's a batch squirreled away to build PLC-3 and PLC-5 parts for the Dept. of Defense.

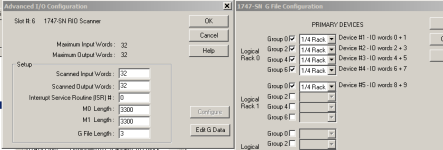

The 1747-SN basic functionality is pretty straightforward: it has 32 words of data addressed to the Slot number. For a 1747-SN in Slot 4, the user program has access to:

I:4.0/0-15

I:4.1/0-15

[...]

I:4.31/0-15

O:4.0/0-15

O:4.1/0-15

[...]

O:4.31/0-15

The old RIO addressing scheme used octal "rack" numbers but with the SLC it uses decimal word and bit numbers. Because the 1747-SN only supports four "racks" worth of adapters, octal rack numbers 0,1,2,3 use the same digits as decimal.

When used with AC drives like the 1336 Plus, Plus II and 1305, the basic setup was each drive = "1/4 Rack" of 2 words input and output, but you could also do larger 1/2, 3/4, and Full rack increments.

The first 1305 drive attached to the network would be Rack 0, Group 0, and would be addressed like:

I:4.0/0-15 = Status Word

I:4.1 = Feedback Word

O:4.0/0-15 = Command Word (Start/Stop/Fwd/Rev/Reset)

O:4.1 = Reference Word (0-32767 = Min Hz to Max Hz)

If you wanted to use the I/O image for transfer of other parameters you could set them up two at a time as "Data Links".

If I had to connect just 5 drives to a 1747-SN, I would probably set them up as "1/2 Racks" and configure them for some extra parameter feedback like fault codes. 5 x 1/2 Racks = 2.5 of the available 4 blocks of addressable memory.

But you could simplify them and do just 2 words each as well.

When examining a system I'd start by looking for the Start/Stop bits and seeing which Word of the 1747-SN slot they are in, which will allow me to infer the Rack/Group addressing of the drives without examining the DIP switches. If they're offset by just 2 words (0, 2, 4, 6, 8) the drives are using the smallest data configuration of "1/4 rack".

RIO and DH+ share the same signal and wiring but different protocols. The SLC-5/04 has a DH+ port built into the CPU, but can have a RIO Scanner module in any slot (more than one, up to a memory limit).

It's a "Manchester-encoded" signal, where the timing of the rising and falling edges makes a 1 or 0, not the signal level. The signal interface is remarkably tolerant of installation and noise problems, to the point where it really spoiled A-B users for less rugged but faster modern networking.

But time marches on, and the chips aren't economical to produce anymore, so A-B bought their last batch five or so years ago and demand will dictate future prices. Probably there's a batch squirreled away to build PLC-3 and PLC-5 parts for the Dept. of Defense.

The 1747-SN basic functionality is pretty straightforward: it has 32 words of data addressed to the Slot number. For a 1747-SN in Slot 4, the user program has access to:

I:4.0/0-15

I:4.1/0-15

[...]

I:4.31/0-15

O:4.0/0-15

O:4.1/0-15

[...]

O:4.31/0-15

The old RIO addressing scheme used octal "rack" numbers but with the SLC it uses decimal word and bit numbers. Because the 1747-SN only supports four "racks" worth of adapters, octal rack numbers 0,1,2,3 use the same digits as decimal.

When used with AC drives like the 1336 Plus, Plus II and 1305, the basic setup was each drive = "1/4 Rack" of 2 words input and output, but you could also do larger 1/2, 3/4, and Full rack increments.

The first 1305 drive attached to the network would be Rack 0, Group 0, and would be addressed like:

I:4.0/0-15 = Status Word

I:4.1 = Feedback Word

O:4.0/0-15 = Command Word (Start/Stop/Fwd/Rev/Reset)

O:4.1 = Reference Word (0-32767 = Min Hz to Max Hz)

If you wanted to use the I/O image for transfer of other parameters you could set them up two at a time as "Data Links".

If I had to connect just 5 drives to a 1747-SN, I would probably set them up as "1/2 Racks" and configure them for some extra parameter feedback like fault codes. 5 x 1/2 Racks = 2.5 of the available 4 blocks of addressable memory.

But you could simplify them and do just 2 words each as well.

When examining a system I'd start by looking for the Start/Stop bits and seeing which Word of the 1747-SN slot they are in, which will allow me to infer the Rack/Group addressing of the drives without examining the DIP switches. If they're offset by just 2 words (0, 2, 4, 6, 8) the drives are using the smallest data configuration of "1/4 rack".