Hello everyone,

I just started a new project but want to make sure I am heading to a correct direction before I am too far down the wrong way.

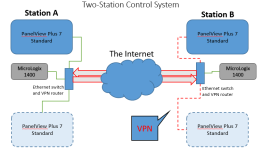

the set up: there are two stations A and B communicating through internet. station A has a micrologix 1400 and AB panelview plus standard(I brought this up because the standard version only can talk to one controller at a time). Station B has a micrologix 1400 and AB panelview plus standard. I want to make two duplicate panelview on both station. I am thinking doing all the controls in station A, and have both panelviews point to station A PLC. Panelview at station A is okay for sure, but I am wondering if station B's panelview is able to communicating to station A's PLC over the internet.

I have never done this before, if anyone has suggestions on how I should approach, I really appreciate it.

I just started a new project but want to make sure I am heading to a correct direction before I am too far down the wrong way.

the set up: there are two stations A and B communicating through internet. station A has a micrologix 1400 and AB panelview plus standard(I brought this up because the standard version only can talk to one controller at a time). Station B has a micrologix 1400 and AB panelview plus standard. I want to make two duplicate panelview on both station. I am thinking doing all the controls in station A, and have both panelviews point to station A PLC. Panelview at station A is okay for sure, but I am wondering if station B's panelview is able to communicating to station A's PLC over the internet.

I have never done this before, if anyone has suggestions on how I should approach, I really appreciate it.