You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Programming S-curve motion profiles

- Thread starter TurkSaleh

- Start date

JRW

Member

Do you actually have to run a motion profile or do you just need to generate a speed reference as an s-ramp from the PLC? Can you provide more information about the actual application?

I think I miss-used the terms here. Indeed the speed reference with smooth acceleration at the start/stop will be enough.

Peter Nachtwey

Member

If TurkSaleh is using a Siemens PLC I recommend he takes JRW's advice and use the library. We have played with it for comparison. It will work. It is better to use a library that has been debugged than to try to re-invent the wheel.

drbitboy, break out your python and sympy and solve the 17 equations for 17 unknowns. Assuming all 7 segments are used the 17 unknowns are

t01, x1, v1, t12, x2, v2, t23, x3, t34, x4, t45, x5, v5, t56, x6, v6, t67

This assume point 0 is the starting point and x7 is the ending point.

The initial and final PVA are known and and commanded P, V, A are given.

In my case the motion controller must be able generate any motion profile the customer wants. Whether the equipment can actually follow it is up to the designers.

drbitboy, break out your python and sympy and solve the 17 equations for 17 unknowns. Assuming all 7 segments are used the 17 unknowns are

t01, x1, v1, t12, x2, v2, t23, x3, t34, x4, t45, x5, v5, t56, x6, v6, t67

This assume point 0 is the starting point and x7 is the ending point.

The initial and final PVA are known and and commanded P, V, A are given.

Probably not but we don't know for sure.you do not need everything Peter is referencing.

In my case the motion controller must be able generate any motion profile the customer wants. Whether the equipment can actually follow it is up to the designers.

I mentioned before the commanded acceleration and velocity may not be reached when making short moves. In this case there are only 3 segments and the motion is jerk limited.The OP mentions 7-segment profiles, which implies the former.

drbitboy

Lifetime Supporting Member

I mentioned before the commanded acceleration and velocity may not be reached when making short moves. In this case there are only 3 segments and the motion is jerk limited.

What I meant was, is it acceleration or jerk that has a Heaviside Function-like profile i.e. is discontinuous.

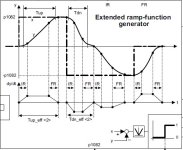

The Siemens library image from JRW looks like acceleration is discontinuous.

Peter Nachtwey

Member

What I meant was, is it acceleration or jerk that has a Heaviside Function-like profile i.e. is discontinuous.

The Siemens library image from JRW looks like acceleration is discontinuous.

The motion profiles I saw on a S7-1500T were true 7 segment motion profiles. They just weren't optimal. They were not easy to use either but the accelerations were either constant or ramp up or down depending on the jerk rate. The segments were continuous. Only the jerk changed in steps.

Where is the solutions for the 17 unknowns?

drbitboy

Lifetime Supporting Member

Where is the solutions for the 17 unknowns?

Where are the equations? The delta link is broken, or maybe I missed it.

Peter Nachtwey

Member

So where is your solution? If you don't know the equations then programming them or how much time it takes to execute them doesn't make much difference. Turbine controls are easy.It's not too difficult.

drbitboy, you are supposed to derive them using sympy.

Siemens has a library somewhere. What JRW presented was not it.

An old thread on s-curves

http://www.plctalk.net/qanda/showthread.php?t=35902&page=2

Last edited:

JRW

Member

drbitboy, you are supposed to derive them using sympy.

Siemens has a library somewhere. What JRW presented was not it.

It’s not supported with g120 , DSC is not supported and telegram 105 is needed

busarider29

Lifetime Supporting Member

Delta is going to add Ethercat capability sometime this year. It will be used mostly to control output devices like valves and drives.

The problem I have with Ethercat is that the packets are essentially CAN Open packets on Ethernet. The CAN Open packets have 8 bytes of data. 8 bytes permit sending a 32 bit float and some command bits that tell what the float is. Usually the float is a position. While it is possible to move from position to position every 50 microseconds there is no feed forward data or target velocity and acceleration, just a target position. This is why I think Ethercat is great for sending output values to valves and drives but not so good for sending motion profiles to multiple controllers.

Very good. I've reached out to Delta with inquiries about the availability of EtherCAT in their controllers and I've not gotten much back in terms of a timeline. Our next machine build is scheduled for end of this year but we're about to start ordering our grocery list of components now, to include the RMC-200 controller.

There were a couple of new standards of EtherCAT released last year, broadband EtherCAT-G and G10. It's intended for transmitting high volumes of data for such things as motion and vision applications. I'm not real familiar with them and only have explored them briefly.

EtherCAT G and G10

More EtherCAT G and G10

Last edited:

JRW

Member

Good

And Peter thought only an RMC could do it

And Peter thought only an RMC could do it

Peter Nachtwey

Member

I didn't say that.Good

And Peter thought only an RMC could do it

I did say Siemens has a library that would do an OK job but...

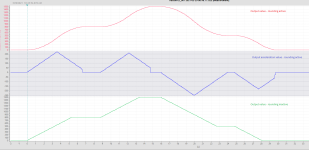

Why are the discontinuities in the output acceleration ( dark blue line )? This is not good.

The red line looks like it is the integral of the blue line or velocity.

The green line looks like velocity without s-curves.

The RMC can do it better.

I am still waiting for someone to find the equations for the 17 variables I listed above. If you don't know the formulas for this variable then how can you say that writing the code in a PLC is easy? It is obvious that Siemens hasn't got it right yet in even a simple case above.

JRW, I still remember you called me arrogant. You do know that Siemens used RMC100s for their plastics solution in the late 1990s and early 2000 until Siemens came out with their own solution. I don't think either Siemens or Delta do much in plastics now because too many OEMs want a package they made themselves where as Delta and Siemens sell components and some assembly is required. We do sell a few RMC75s for plastic applications on retrofits.

Peter Nachtwey

Member

I didn't say that.Good

And Peter thought only an RMC could do it

I did say Siemens has a library that would do an OK job but...

Why are the discontinuities in the output acceleration ( dark blue line )? This is not good.

The red line looks like it is the integral of the blue line or velocity.

The green line looks like velocity without s-curves.

The RMC can do it better.

I am still waiting for someone to find the equations for the 17 variables I listed above. If you don't know the formulas for this variable then how can you say that writing the code in a PLC is easy? It is obvious that Siemens hasn't got it right yet in even a simple case above.

JRW, I still remember you called me arrogant. You do know that Siemens used RMC100s for their plastics solution in the late 1990s and early 2000 until Siemens came out with their own solution. I don't think either Siemens or Delta do much in plastics now because too many OEMs want a package they made themselves where as Delta and Siemens sell components and some assembly is required. We do sell a few RMC75s for plastic applications on retrofits.

Similar Topics

Hey everyone,

I have a sensor that gives a 4 - 20 mA signal that is not perfectly linear. There is a bit of a curve in it. I would like to hook...

- Replies

- 27

- Views

- 4,705

Does anyone can explain me how to do s-curve (for increasing and decreasing speed of the process ) programming in siemens simatic S7.

If...

- Replies

- 1

- Views

- 1,871

Hi all,

i am the new controls guy at the plant and i have inherited a pc from the previous controls guy with Siemens tia portal version 16 and 17...

- Replies

- 17

- Views

- 638

I need to pull the program off of an old 90-30 so I can convert it to Allen Bradley. This is my first time messing with GE and I don't have the...

- Replies

- 2

- Views

- 81

New to vfds. I put in parameters. IP, but I get ethernet flashing and link solid. What did I do wrong?

- Replies

- 9

- Views

- 447