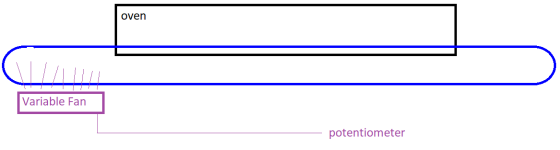

Hello, I got a customer that has a shrink wrap machine to bundle up beer cans to make beer packs. They have a problem with the oven's all metal belt conveyor. When the belt gets too hot, the shrink wrap stinks on the belt and if the belt is too cold, the wrap doesn't shrink under the pack.

The machine has a big fan to cool the belt but it's manually operated with a potentiometer. If the operator notices that the wrap sticks, he turns the fan to a higher speed and if the wrap doesn't shrink under the pack, he turns the fan to a lower speed.

They would like to regulate/automate the belt temperature. A VFD will be installed.

I was thinking a simple PID temperature loop with the fan. A temperature probe would be installed after the fan. We would do some tests to figure out the optimal belt temperature in the oven versus the belt temperature after the fan.

Anwybody has a better idea how to achieve this?

Thanks!

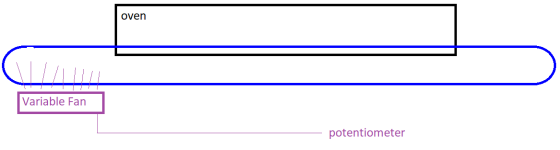

The machine has a big fan to cool the belt but it's manually operated with a potentiometer. If the operator notices that the wrap sticks, he turns the fan to a higher speed and if the wrap doesn't shrink under the pack, he turns the fan to a lower speed.

They would like to regulate/automate the belt temperature. A VFD will be installed.

I was thinking a simple PID temperature loop with the fan. A temperature probe would be installed after the fan. We would do some tests to figure out the optimal belt temperature in the oven versus the belt temperature after the fan.

Anwybody has a better idea how to achieve this?

Thanks!