Hi Experts,

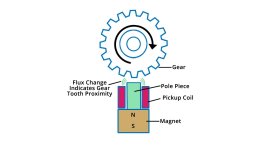

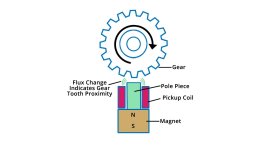

I am reading the engine speed from a magnetic pickup - magentic pickup is placed near the flywheel and when a teeth crosses it produces a pulse the output is an AC Voltage with frequency as speed increases both the voltage and the frequency will increase - and I am using a Phoenix contact transducer to read the frequency and converting that to the RPM inside siemens PLC

The problem I am facing is that when at lower speed the output from the magnetic Pickup is in the order of 200mV and the Phoenix Contact transducer is not able to read the frequency because it needs a minimum 5 Volts

even though the magnetic pickup is rated to produce 15 Vac but in this arrangement it is not able to produce that much

as engine speed up it produces more voltage and then the transducer will be able to read the frequency but i do not want to miss the speed at lower RPM

I need some ideas as how can I amplify the signal without changing the frequency to a a higher voltage minimum 5V and if there is any alternative to the the magneticpickup any other sensor which can count the teeths and I can get the speed

I am reading the engine speed from a magnetic pickup - magentic pickup is placed near the flywheel and when a teeth crosses it produces a pulse the output is an AC Voltage with frequency as speed increases both the voltage and the frequency will increase - and I am using a Phoenix contact transducer to read the frequency and converting that to the RPM inside siemens PLC

The problem I am facing is that when at lower speed the output from the magnetic Pickup is in the order of 200mV and the Phoenix Contact transducer is not able to read the frequency because it needs a minimum 5 Volts

even though the magnetic pickup is rated to produce 15 Vac but in this arrangement it is not able to produce that much

as engine speed up it produces more voltage and then the transducer will be able to read the frequency but i do not want to miss the speed at lower RPM

I need some ideas as how can I amplify the signal without changing the frequency to a a higher voltage minimum 5V and if there is any alternative to the the magneticpickup any other sensor which can count the teeths and I can get the speed

Last edited: