defcon.klaxon

Lifetime Supporting Member

Hi all,

Got a call from a client that has several small water systems, asked me to take a look at one I've never programmed, just troubleshot a previous sensor issue. The CPU is a Siemens Simatric TI335-37, with a TI305 programmer connected to the CPU. This is a Roberts water filtration system (two filters, just FYI) and looks like it was installed in about 1994.

They experienced a power outage for about an hour, and when power restored the plant did not resume filtering water.

I've never programmed or troubleshot Siemens processors of any kind, let alone this old so I'm totally in the dark here.

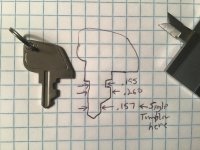

When I arrived I cracked open the cabinet and found that the PWR light was green, but RUN was not illuminated, nor was BATT or CPU. RX and TX also nothing, but there is no comms in this system so I'm not concerned with that. The TI305 programmer is set to RUN, but they don't know where the key is and we couldn't find it after searching high and low.

Luckily they did have the TISOFT2 software on 3.5" diskette, and after a lot of troubleshooting I was able to get it to install on a WinXP VM. We were also able to find another 3.5 diskette with the program on it, but it was dated 1994 so who knows if the program has ever been changed since original installation.

I do have the TISOFT2 manual but my goodness is it ancient. Was wondering if you guys could help with the following questions:

1. I see the the TI315 programmer is removable, and from doing some reading it sounds like the TI315 is more for small projects/troubleshooting rather than larger complex projects. So that makes me think I can interface with the CPU with its RS232 jack directly, is this right?

2. Is there a way to check what, if any, code is currently stored on the CPU?

3. I've read that Automation Direct took over the line and DirectSOFT6 can be used to interface; tried doing this but for some reason it's ignoring my license key and it says failed to import project. This is a long shot, but has anyone else had this issue? I'll try AD tech support too.

I think I've figured out how to move forward, but any insight is sure appreciated. Thanks gents!

edit: I forgot to mention that while the RUN light isn't illuminated on the CPU, the I/O cards do show that when discrete values change (i.e. HOA switches) they DO show change, so the I/O is at least responsive.

Got a call from a client that has several small water systems, asked me to take a look at one I've never programmed, just troubleshot a previous sensor issue. The CPU is a Siemens Simatric TI335-37, with a TI305 programmer connected to the CPU. This is a Roberts water filtration system (two filters, just FYI) and looks like it was installed in about 1994.

They experienced a power outage for about an hour, and when power restored the plant did not resume filtering water.

I've never programmed or troubleshot Siemens processors of any kind, let alone this old so I'm totally in the dark here.

When I arrived I cracked open the cabinet and found that the PWR light was green, but RUN was not illuminated, nor was BATT or CPU. RX and TX also nothing, but there is no comms in this system so I'm not concerned with that. The TI305 programmer is set to RUN, but they don't know where the key is and we couldn't find it after searching high and low.

Luckily they did have the TISOFT2 software on 3.5" diskette, and after a lot of troubleshooting I was able to get it to install on a WinXP VM. We were also able to find another 3.5 diskette with the program on it, but it was dated 1994 so who knows if the program has ever been changed since original installation.

I do have the TISOFT2 manual but my goodness is it ancient. Was wondering if you guys could help with the following questions:

1. I see the the TI315 programmer is removable, and from doing some reading it sounds like the TI315 is more for small projects/troubleshooting rather than larger complex projects. So that makes me think I can interface with the CPU with its RS232 jack directly, is this right?

2. Is there a way to check what, if any, code is currently stored on the CPU?

3. I've read that Automation Direct took over the line and DirectSOFT6 can be used to interface; tried doing this but for some reason it's ignoring my license key and it says failed to import project. This is a long shot, but has anyone else had this issue? I'll try AD tech support too.

I think I've figured out how to move forward, but any insight is sure appreciated. Thanks gents!

edit: I forgot to mention that while the RUN light isn't illuminated on the CPU, the I/O cards do show that when discrete values change (i.e. HOA switches) they DO show change, so the I/O is at least responsive.

Last edited: