jri4au

Member

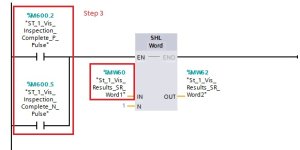

I am having difficulty understanding how to write this station. I have run into conflicting information and am looking for some ideas. The camera is sending a pass and job complete, I need to reject it at some point downstream. The sample I was given is not helping

job -------------job----- one --------------- index

---||-------------||--------[]-------------------()

complete-------pass-----shot----|------------bit

----------------------------------BSL

What is the one shot doing here, or the index bit? If I am right, job pass writes a 1 to the shift register, when it doesn't a zero is entered. Each cycle it shifts until you get ready to UL. Can I use the zero in the UL to kick the fail? Writing it this way how does the processor know to write the 0 to the register. Hopefully you guys see the gap in my training and can help. Thanks

job -------------job----- one --------------- index

---||-------------||--------[]-------------------()

complete-------pass-----shot----|------------bit

----------------------------------BSL

What is the one shot doing here, or the index bit? If I am right, job pass writes a 1 to the shift register, when it doesn't a zero is entered. Each cycle it shifts until you get ready to UL. Can I use the zero in the UL to kick the fail? Writing it this way how does the processor know to write the 0 to the register. Hopefully you guys see the gap in my training and can help. Thanks

Last edited: