hrohibil

Member

Hi everyone.

Happy new year to you all. Im glad to find a forum such as this.

I am new in the programming world of PLC.

I am selfstuding so my knowedge comes from books, internet and a short 2 days course I while back ago.

I want to understand the values 0 and 1 in relation to NO and NC inputs.

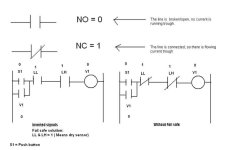

I have attached a simpel drawing of 2 ladderdiagrams. They basiclly do the same function, but the first ladder has a fail safe solution, so that the input signals are inverted from 0 to 1.

I allways thought that 0 was shut off and 1 was turned on, I mean how can NO input be 1. When a signal is 1 there should be current running to it right?

Can someone please explain to me from the first ladder from my drawing ( the left one) if I hit the S1/push button, how can there come an signal trough to the output V1, when the 2 lewel swithes LL and LH are Normally opened?

Can they be normally open and be a 1 signal?

Sorry for the long explanation, I hope someone can help me..

Best regards Hamid

Happy new year to you all. Im glad to find a forum such as this.

I am new in the programming world of PLC.

I am selfstuding so my knowedge comes from books, internet and a short 2 days course I while back ago.

I want to understand the values 0 and 1 in relation to NO and NC inputs.

I have attached a simpel drawing of 2 ladderdiagrams. They basiclly do the same function, but the first ladder has a fail safe solution, so that the input signals are inverted from 0 to 1.

I allways thought that 0 was shut off and 1 was turned on, I mean how can NO input be 1. When a signal is 1 there should be current running to it right?

Can someone please explain to me from the first ladder from my drawing ( the left one) if I hit the S1/push button, how can there come an signal trough to the output V1, when the 2 lewel swithes LL and LH are Normally opened?

Can they be normally open and be a 1 signal?

Sorry for the long explanation, I hope someone can help me..

Best regards Hamid