Hi,

I have just started learning PLC programming by using TLP LogixPro Simulator. I'm now doing the Door simulation to Open and Close the door.

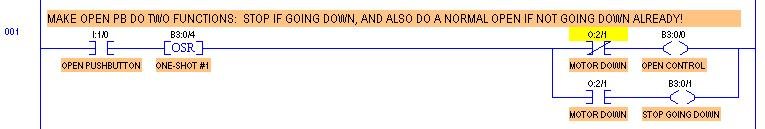

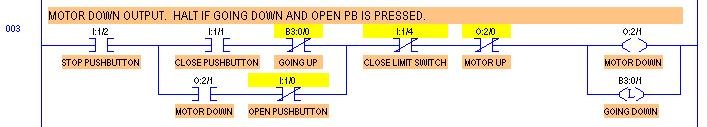

I've written the ladder logic program for the following scenario:

1) When the door is opening (Motor UP is rotating), pressing CLOSE button 1 time should stop the motor. Pressing CLOSE button the second time should close the door (Motor DOWN is rotating).

2) When the door is closing (Motor DOWN is rotating), pressing OPEN button 1 time should stop the motor. Pressing OPEN button the second time should open the door (Motor UP is rotating).

Note:

When either Motor UP or Motor DOWN is rotating, B3:0/0 (Moving Flag) is latch to high.

Some times the program doesn't work as in when the door is closing (Motor DOWN is rotating), pressing the OPEN button 1 time will cause the door to open (which is not what i wanted). The door should stop first and will only open when the OPEN button is pressed the second time. The reverse process also doesn't work.

Attached is TLP LogixPro Simulator code which I saved and also a print screen of the ladder logic code. Can somebody please advice me on how to make the program more stable and how to make it better.

Thank you very much..

I have just started learning PLC programming by using TLP LogixPro Simulator. I'm now doing the Door simulation to Open and Close the door.

I've written the ladder logic program for the following scenario:

1) When the door is opening (Motor UP is rotating), pressing CLOSE button 1 time should stop the motor. Pressing CLOSE button the second time should close the door (Motor DOWN is rotating).

2) When the door is closing (Motor DOWN is rotating), pressing OPEN button 1 time should stop the motor. Pressing OPEN button the second time should open the door (Motor UP is rotating).

Note:

When either Motor UP or Motor DOWN is rotating, B3:0/0 (Moving Flag) is latch to high.

Some times the program doesn't work as in when the door is closing (Motor DOWN is rotating), pressing the OPEN button 1 time will cause the door to open (which is not what i wanted). The door should stop first and will only open when the OPEN button is pressed the second time. The reverse process also doesn't work.

Attached is TLP LogixPro Simulator code which I saved and also a print screen of the ladder logic code. Can somebody please advice me on how to make the program more stable and how to make it better.

Thank you very much..