PhilipD

Member

Hi all,

Here is a problem I had and have a solution for but I'm wondering is there is a more "eloquent" way.

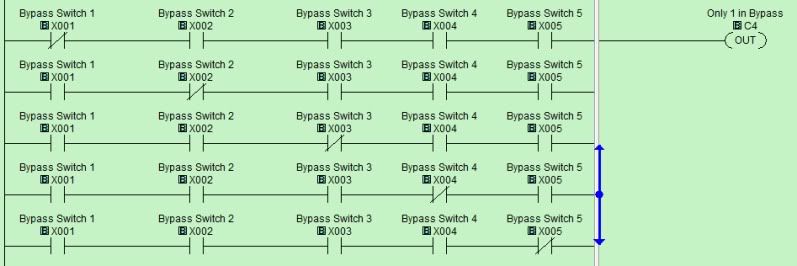

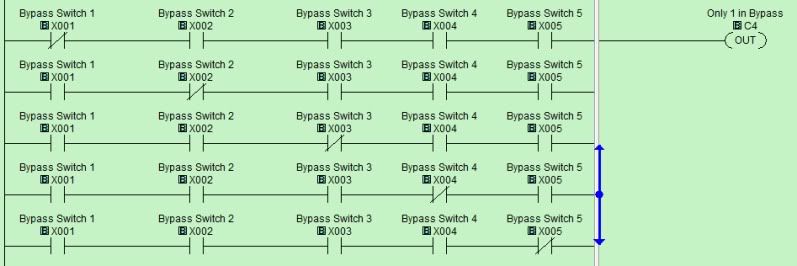

I have 5 two position, maintained switches marked "ON" and "OFF". I need to know when any one (and only one) of the switches is on. Each switch is wired to its own input labeled Bypass Switch 1 through Bypass Switch 5.

I used this code to determine when only one switch is on.

Any suggestions?

Thanks.

Here is a problem I had and have a solution for but I'm wondering is there is a more "eloquent" way.

I have 5 two position, maintained switches marked "ON" and "OFF". I need to know when any one (and only one) of the switches is on. Each switch is wired to its own input labeled Bypass Switch 1 through Bypass Switch 5.

I used this code to determine when only one switch is on.

Any suggestions?

Thanks.

Last edited: