VSandhu

Member

Hello,

I was hoping someone could help me out with a bit of physics.

Currently I have a cart that has 5 inch (diamter) wheels on it. On the drive shaft of the cart, there is an encoder whose resolution is 360 pulses per rev. The Encoder is connected to a Rockwell Compact Logix fixed unit. This fixed unit (1769-L23E-QBFC1) has an input, output, analog in/out and high speed counter on it. Encoder is connected to the High speed counter.

My issue: When the cart does not have a load on it, the wheel diameter is 5". When it is loaded with a heavy weight, the wheel diameter can change by as much as 1/16th of an inch. I dont think the diameter really changes as much as the wheel becomes out of round. I command the cart to travel to a set point based on encoder counts. So lets say the set point is 1000 pulses at a speed of 30 F/M. Based on my little chart below, there are two roll diameter. One is the original 5 inch and the other is 4.9375 which should be 1/16 change when loaded. So when the cart is commanded to the destination, depending on if it is loaded or unloaded, the cart will not travel to the same point because of the diameter change.

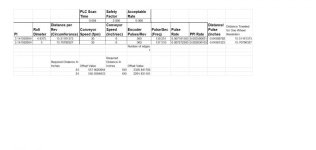

PIRoll DimeterDistance per Rev (Circumferance)Conveyor Speed (fpm)Conveyor Speed (Inch/sec)Encoder Pulses/RevPulse/Sec (Freq)Pulse RatePPI RateDistance/Pulse (InchesDistance Traveled for One Wheel Revolution3.1415926544.937515.51161373306360139.2510.0071813030.0035906510.0430878215.511613733.141592654515.70796327306360137.5100.0072722050.0036361030.0436332315.70796327

My Question: I want to try and correct this error based on encoder pulses captured at a certain distance. So If the cart travels 24 inches with out a load, I should see a count of 550 encoder pulses. If the diameter changes by a 1/16th then I should see 557 pulses for a travel distance of 24inches. In a perfect world I would then compute (557/550)* 1000 (setpoint) = 1012 for the new set point due to the change in wheel diameter. Lets say I have a timer in the PLC where after 4 seconds I capture the encoder counts to execute the calculation shown above. If my speed is a constant set point of 30F/M or 6 Inches/Second, should I be able to capture the increase in pulses. There was some discussion at work, that I would need to have a laser PE that looks at the side rail when the cart is traveling. The side rail has two holes spaced 24 inches apart. So when the PE sees the first hole I start capturing encoder counts, when the PE sees the second hole in the rail, I capture the count again. Then I would subtract the two and I should see around 550 pulses. Cant I do the same as I described without the Photo eye? I understand the complications of using timers and so forth in a PLC, my question is if the PLC were perfect, can I get the increase in counts with a timer.

Thanks in advance for any help you can provide

I was hoping someone could help me out with a bit of physics.

Currently I have a cart that has 5 inch (diamter) wheels on it. On the drive shaft of the cart, there is an encoder whose resolution is 360 pulses per rev. The Encoder is connected to a Rockwell Compact Logix fixed unit. This fixed unit (1769-L23E-QBFC1) has an input, output, analog in/out and high speed counter on it. Encoder is connected to the High speed counter.

My issue: When the cart does not have a load on it, the wheel diameter is 5". When it is loaded with a heavy weight, the wheel diameter can change by as much as 1/16th of an inch. I dont think the diameter really changes as much as the wheel becomes out of round. I command the cart to travel to a set point based on encoder counts. So lets say the set point is 1000 pulses at a speed of 30 F/M. Based on my little chart below, there are two roll diameter. One is the original 5 inch and the other is 4.9375 which should be 1/16 change when loaded. So when the cart is commanded to the destination, depending on if it is loaded or unloaded, the cart will not travel to the same point because of the diameter change.

PIRoll DimeterDistance per Rev (Circumferance)Conveyor Speed (fpm)Conveyor Speed (Inch/sec)Encoder Pulses/RevPulse/Sec (Freq)Pulse RatePPI RateDistance/Pulse (InchesDistance Traveled for One Wheel Revolution3.1415926544.937515.51161373306360139.2510.0071813030.0035906510.0430878215.511613733.141592654515.70796327306360137.5100.0072722050.0036361030.0436332315.70796327

My Question: I want to try and correct this error based on encoder pulses captured at a certain distance. So If the cart travels 24 inches with out a load, I should see a count of 550 encoder pulses. If the diameter changes by a 1/16th then I should see 557 pulses for a travel distance of 24inches. In a perfect world I would then compute (557/550)* 1000 (setpoint) = 1012 for the new set point due to the change in wheel diameter. Lets say I have a timer in the PLC where after 4 seconds I capture the encoder counts to execute the calculation shown above. If my speed is a constant set point of 30F/M or 6 Inches/Second, should I be able to capture the increase in pulses. There was some discussion at work, that I would need to have a laser PE that looks at the side rail when the cart is traveling. The side rail has two holes spaced 24 inches apart. So when the PE sees the first hole I start capturing encoder counts, when the PE sees the second hole in the rail, I capture the count again. Then I would subtract the two and I should see around 550 pulses. Cant I do the same as I described without the Photo eye? I understand the complications of using timers and so forth in a PLC, my question is if the PLC were perfect, can I get the increase in counts with a timer.

Thanks in advance for any help you can provide