suchitradevi79

Member

Hi i have got a small project where i was asked to do relay logic for and annunciator panel.

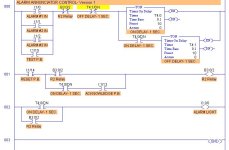

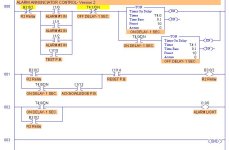

The lamp should flicker incase of error,and when acknowledged with a pushbutton, it should be steady-ON.

How can do this by using relay logic. When reset is pressed after error is cleared, the lamp should be OFF.

It is the easy for me to do ladder logic for this. but i dont know relay logic.

Please someone help me

The lamp should flicker incase of error,and when acknowledged with a pushbutton, it should be steady-ON.

How can do this by using relay logic. When reset is pressed after error is cleared, the lamp should be OFF.

It is the easy for me to do ladder logic for this. but i dont know relay logic.

Please someone help me