please help i didn't solve this problem with rslogix. I counted but i am not using timer. How i will fix this situation? Please anyone solve this.

1000 for quality control or inspection purposes.

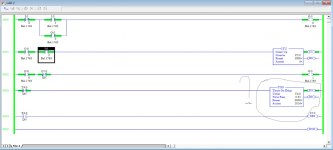

The circuit operates as follows:

• A start/stop pushbutton station is used to turn the

conveyor motor on and off.

• A proximity sensor counts the parts as they pass

by on the conveyor.

• When a count of 1000 is reached, the counter’s

output activates the gate solenoid, diverting the

part to the inspection line.

• The gate solenoid is energized for 2 s, which

allows enough time for the part to continue to the

quality control line.

• The gate returns to its normal position when the

2-s time period ends.

• The counter resets to 0 and continues to

accumulate counts.

• A reset pushbutton is provided to reset the

counter manually.

1000 for quality control or inspection purposes.

The circuit operates as follows:

• A start/stop pushbutton station is used to turn the

conveyor motor on and off.

• A proximity sensor counts the parts as they pass

by on the conveyor.

• When a count of 1000 is reached, the counter’s

output activates the gate solenoid, diverting the

part to the inspection line.

• The gate solenoid is energized for 2 s, which

allows enough time for the part to continue to the

quality control line.

• The gate returns to its normal position when the

2-s time period ends.

• The counter resets to 0 and continues to

accumulate counts.

• A reset pushbutton is provided to reset the

counter manually.