industrial

Member

Has anyone had similar issues to the one I'm experiencing at the moment?

We have had a process running successfully on a ML1400 for a number of months. RFID ASCII data coming in on both Channel 0 and 2 which is processed and stored in arrays. The data is accessed remotely (Ethernet) over company network using INGEAR drivers to SQL database.

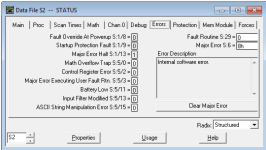

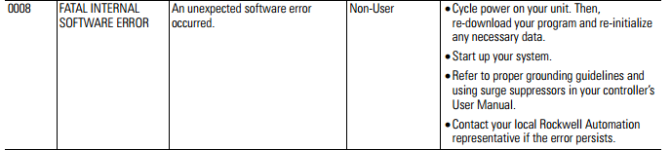

About six weeks ago the Processor started to fault, indicating "internal Software Fault" The program was re-installed and ran again all day with no problem. A search found possibility of power spikes being a possible cause. With a number of VSD's in the vicinity this was quite possible.

To date I have installed Surge suppression on incoming power supply, data isolator-repeaters on RS232 transmission lines and isolated the I/O with opto relays. The receiving App indicates the fault happens around 12:30 in the night.

I have swapped out the ML1400 with a spare numerous times but both fault at the same time. I then had both of them in the office some 100 meters from the PLC cabinet. One had the process program running and I can see the remote app polling the PLC for data every second. The other processor had a test program running, both connected to a CISCO 2960 managed switch.

When I came in the next morning they had both faulted... this would lead me to belief that either the site server or the managed switch is causing the problem??

We have had a process running successfully on a ML1400 for a number of months. RFID ASCII data coming in on both Channel 0 and 2 which is processed and stored in arrays. The data is accessed remotely (Ethernet) over company network using INGEAR drivers to SQL database.

About six weeks ago the Processor started to fault, indicating "internal Software Fault" The program was re-installed and ran again all day with no problem. A search found possibility of power spikes being a possible cause. With a number of VSD's in the vicinity this was quite possible.

To date I have installed Surge suppression on incoming power supply, data isolator-repeaters on RS232 transmission lines and isolated the I/O with opto relays. The receiving App indicates the fault happens around 12:30 in the night.

I have swapped out the ML1400 with a spare numerous times but both fault at the same time. I then had both of them in the office some 100 meters from the PLC cabinet. One had the process program running and I can see the remote app polling the PLC for data every second. The other processor had a test program running, both connected to a CISCO 2960 managed switch.

When I came in the next morning they had both faulted... this would lead me to belief that either the site server or the managed switch is causing the problem??