dogfart

Lifetime Supporting Member

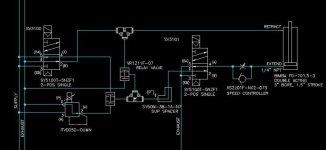

Hello all. I am hoping to get a second set of eyes on something that I have been working on. I am trying to salvage the use of a SMC serial transmission device EX250-SEN1 and utilizing SY5000 series valves. I am looking to control a cylinder with an ItoP regulator. I have two things I am trying to accomplish here:

1. maintain pilot pressure (this is an external supply port)

2. start the regulator controlling from atmoshperic pressure

SV3100 and SV3101 are always operated in parallel. Part of me thinks I might be overcomplicating the issue, or perhaps there is a better solenoid combination to use other than the 2-pos singles that I have in the jpeg.

Thanks

1. maintain pilot pressure (this is an external supply port)

2. start the regulator controlling from atmoshperic pressure

SV3100 and SV3101 are always operated in parallel. Part of me thinks I might be overcomplicating the issue, or perhaps there is a better solenoid combination to use other than the 2-pos singles that I have in the jpeg.

Thanks