Outrage

Member

Hello, I'm trying to configure Profibus communications between a CPU315-2 PN/DP and a Parker 590 DC drive fitted with a L5353 profibus card.

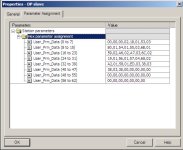

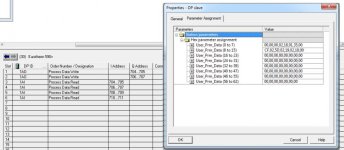

I've got as far as installing the GSD in Step 7 and looking through the profibus manuals off the Parker website but quite frankly the method of parameterisation is stumping me, plus all of Parkers example documentation seems to display COM-Profibus examples which seems a bit old hat and I'm strugging to transpose that into Step 7 HW Config format.

Does anyone have any parameterisation configuration examples they can post? I have a support call in with Parker at the moment in which they have given me reference to the parameter tags I require and pointed me in the diection of the manuals which I already have.

The drive has been supplied, configured and installed by Parker onsite and I don't have access to it until commissioning starts. so any help would be appreciated!

I've around 20 other devices hanging on the same network ranging from digital meters to torque transducers that have all been well documented but this kit is something else...

Cheers,

Lee

I've got as far as installing the GSD in Step 7 and looking through the profibus manuals off the Parker website but quite frankly the method of parameterisation is stumping me, plus all of Parkers example documentation seems to display COM-Profibus examples which seems a bit old hat and I'm strugging to transpose that into Step 7 HW Config format.

Does anyone have any parameterisation configuration examples they can post? I have a support call in with Parker at the moment in which they have given me reference to the parameter tags I require and pointed me in the diection of the manuals which I already have.

The drive has been supplied, configured and installed by Parker onsite and I don't have access to it until commissioning starts. so any help would be appreciated!

I've around 20 other devices hanging on the same network ranging from digital meters to torque transducers that have all been well documented but this kit is something else...

Cheers,

Lee