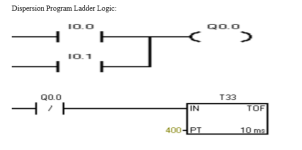

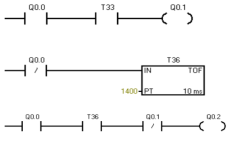

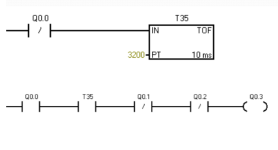

I have a mixing tank program in RSlogix, I'm trying to write a dispersion program after the mixing cycle is done. I'm having a little bit of trouble with transition from one to the other and the proper I/O addresses. I have attached the report and mixing tank program. Any help would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PLC-Agricultural and Mixing tank program

- Thread starter Oddz313

- Start date

danatomega

Lifetime Supporting Member

You have not actually attached anything. Please try again.

Tom Jenkins

Lifetime Supporting Member

If this is your senior project you are unlikely to have anyone on this forum do it for you or give you answers. We will suggest approaches and critique your work

The first step in any program is to create a description of the function. What is the dispersion process supposed to do? Write this in plain English - not code.

The next step is to create an I/O point list - what are the analog and discrete inputs and outputs?

Then create a list of alarms - when should the operator be made aware of events?

Then create a list of adjustments - what will the operator need to change to tune the system?

Then you can begin to write the logic. It is pointless to try to write logic until you understand how the system is supposed to work.

The first step in any program is to create a description of the function. What is the dispersion process supposed to do? Write this in plain English - not code.

The next step is to create an I/O point list - what are the analog and discrete inputs and outputs?

Then create a list of alarms - when should the operator be made aware of events?

Then create a list of adjustments - what will the operator need to change to tune the system?

Then you can begin to write the logic. It is pointless to try to write logic until you understand how the system is supposed to work.

Well, actually as a student, he/she has already put in more work than we are used to seeing around here.

But like Tom says, you need to create a sequence of operation and an I/O list, if for no other reason so that those of us following along at home don't have to try to guess what your I/O is supposed to do.

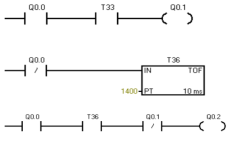

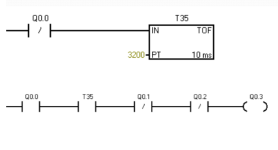

Squinting at your code it looks like you are on the right track. Do what Tom suggests (do at least the first two, I don't know that alarms and adjustments are necessary for this project, and in the real world, maybe, maybe not).

But like Tom says, you need to create a sequence of operation and an I/O list, if for no other reason so that those of us following along at home don't have to try to guess what your I/O is supposed to do.

Squinting at your code it looks like you are on the right track. Do what Tom suggests (do at least the first two, I don't know that alarms and adjustments are necessary for this project, and in the real world, maybe, maybe not).

My school

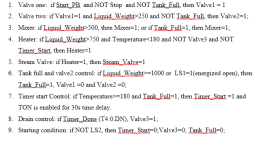

It's a research school with foriegn instructors that don't care much for teaching. Most things in engineering I taught myself around there. They still expect a lot though. I have attached location list for mixing tank program, I just need help with a transition to a small program that waters the plots for so many seconds.

It's a research school with foriegn instructors that don't care much for teaching. Most things in engineering I taught myself around there. They still expect a lot though. I have attached location list for mixing tank program, I just need help with a transition to a small program that waters the plots for so many seconds.

Much better. Not great, mind you, but better. LS1 and LS2 need better descriptions, but for now, I'm going with LS1 as your Low Level Switch and LS2 as your High Level Switch.

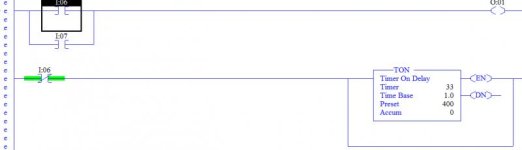

Based on this, rung 5 should seal itself in once it turns on indicating a full tank until you make LS1. That way you can use B3:0/3 as the start of your dispensing logic. If you do this, be sure to revisit any rung that uses B3:0/3 (I'm looking at you, rung 2...)

Rung 4 simply drives the steam valve, why not get rid of B3:0/2 in the previous rung and drive the output directly in rung 3? Unless it's a requirement made by your instructors, and if that"s the case, it's time to revisit rungs 0 - 2...

Is this supposed to be a continuous process? Or more along the lines of a batch where you fill, mix, and heat the liquids and then dispense them?

Please post the entire program as a RSLogix file and/or post the entire ladder logic as a .pdf. Searching between the various clips is making my head hurt. Owww...

As for your instructors, they remind me of my partner at work, whose instructor told him when he asked for help "That if he didn't already know the answer, he couldn't help him". Nice...

Based on this, rung 5 should seal itself in once it turns on indicating a full tank until you make LS1. That way you can use B3:0/3 as the start of your dispensing logic. If you do this, be sure to revisit any rung that uses B3:0/3 (I'm looking at you, rung 2...)

Rung 4 simply drives the steam valve, why not get rid of B3:0/2 in the previous rung and drive the output directly in rung 3? Unless it's a requirement made by your instructors, and if that"s the case, it's time to revisit rungs 0 - 2...

Is this supposed to be a continuous process? Or more along the lines of a batch where you fill, mix, and heat the liquids and then dispense them?

Please post the entire program as a RSLogix file and/or post the entire ladder logic as a .pdf. Searching between the various clips is making my head hurt. Owww...

As for your instructors, they remind me of my partner at work, whose instructor told him when he asked for help "That if he didn't already know the answer, he couldn't help him". Nice...

First ZIP or compress your file and save it as a *.ZIP file. Then we can download and convert back to a RSS file. That will allow searching and organizing the program. You need rung comments, address comments, and section Titles to help define the different sections.I'm having trouble attaching the file from RSlogix.

It appears to me that you could use Step relays (or a step number) to control each section, and move from one section to the next. that way you can insert a new routine at any point in the program.

Looking farther, one of the main things you need right away is a RUN internal relay, that is ON when all the start conditions in Item 9 are met. You will need logic to reset the various timers and start conditions. Then when the Start Pushbutton is pressed, the internal RUN relay should be ON. When STOP is pressed (or the process is completed), RUN should go off. Then all the other steps should follow in a sequence.

Last edited:

I see that you must follow the instructions in your problem. You need to add the dispersion routine by adjusting the addreses with offsets to allow adding on to your existing Inputs and Outputs, as shown in the attached file.

You should remove all Forces from your program, and also correct a NO/NC mistake or two.

You should remove all Forces from your program, and also correct a NO/NC mistake or two.

Last edited:

Similar Topics

The past week we received a new piece of equipment from Germany which utilizes siemens controls. Typically in our company we use A.B. controls for...

- Replies

- 4

- Views

- 48

the conveyor can stop because of a safety sensor or safety switch. And also it can stop because of an object jam detector sensor. If the conveyor...

- Replies

- 5

- Views

- 123

Good Day to all of you, this is my first post, i will try to explain as best as possible, english is not my natural language. I am performing an...

- Replies

- 0

- Views

- 29

Hi All,

Someone at work has put a PLC system on my desk, that's just been taken off an idle production line.

He said "It's an S7 PLC. We don't...

- Replies

- 10

- Views

- 206

I have a project to automate four generator sets. The system will monitor and store the load demand of the factory. Once there's Power outage, the...

- Replies

- 0

- Views

- 57