Hi to all! Need some help!

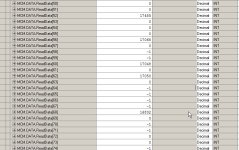

I'm reading CATERPILLAR engine data of a natural gas compressor into my

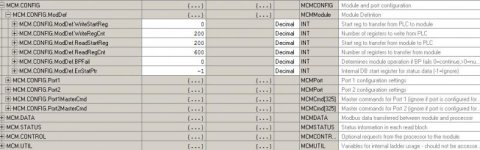

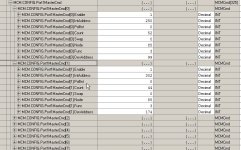

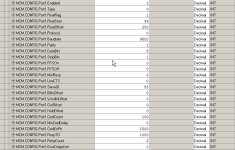

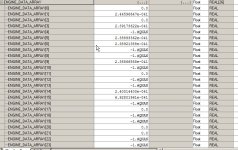

MVI56E-MCM card. The card sits in a 14 slot ControlLogix rack. My Modbus read data arrays are mapped to CAT modbus addresses.

According to the information given by CAT engineer,

1 >each engine parameter needs 2 16 bit modbus registers

2 >values are signed 32

3 >values are pre-scaled using 32 float

4 >my MCM uses 16 bit INT for one register.

MCM can read data from engine but the values are not seems accurate.

I would like to know how to combine this two registers coming from the engine and correctly interpret them to the actual engine data in respective units. Any binary conversion needed? do need to apply the scaling formulas?

thanks in advance

I'm reading CATERPILLAR engine data of a natural gas compressor into my

MVI56E-MCM card. The card sits in a 14 slot ControlLogix rack. My Modbus read data arrays are mapped to CAT modbus addresses.

According to the information given by CAT engineer,

1 >each engine parameter needs 2 16 bit modbus registers

2 >values are signed 32

3 >values are pre-scaled using 32 float

4 >my MCM uses 16 bit INT for one register.

MCM can read data from engine but the values are not seems accurate.

I would like to know how to combine this two registers coming from the engine and correctly interpret them to the actual engine data in respective units. Any binary conversion needed? do need to apply the scaling formulas?

thanks in advance