don2405

Member

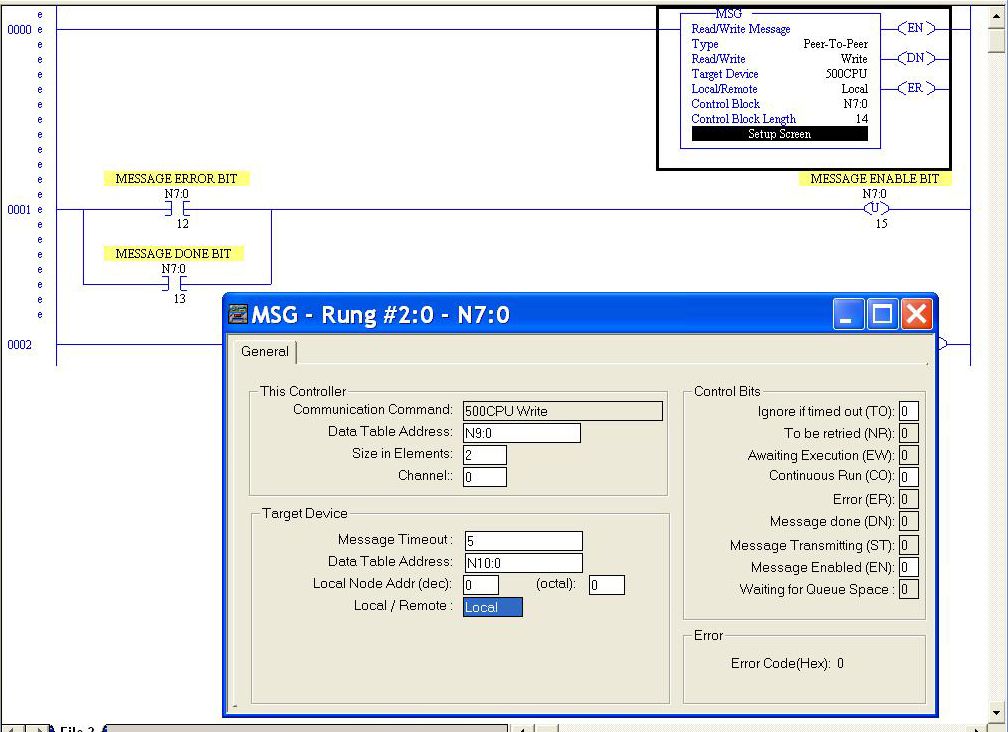

I am new to using the rslogix 500 msg instruction, I am getting problems setting it up.

I have two a slc 5/03,s connected to ethernet via 1761- net eni, both devices seen on rs linx.

I want to have an input triggered in one plc and the output come on the other plc, after then i will try the communications monitoring (heartbeat) setup(with help from this site.

On the message instruction I configured:

Read/write: Write

Target device: 500 cpu

Control block: N7:0

SETUP SCREEN

table address: N7:0

size element: 1

channel: 0

target device

timeout: 5

table address: N7:1

Node: 0

No success, I got this message on the setup screen: no ip address configured on network.

Please, can i get some pointers?

I have two a slc 5/03,s connected to ethernet via 1761- net eni, both devices seen on rs linx.

I want to have an input triggered in one plc and the output come on the other plc, after then i will try the communications monitoring (heartbeat) setup(with help from this site.

On the message instruction I configured:

Read/write: Write

Target device: 500 cpu

Control block: N7:0

SETUP SCREEN

table address: N7:0

size element: 1

channel: 0

target device

timeout: 5

table address: N7:1

Node: 0

No success, I got this message on the setup screen: no ip address configured on network.

Please, can i get some pointers?

Last edited: