I've been beating my head against this problem intermittently for a while now.

We have 3 meter with hard mechanical counters on the top that go up to 99,999,999.99 and then roll over to 0. We only use them as a verification/check against our flow computer for the indicated volume.

I'm using Wonderware v10.6 and RSLogix5000.

Currently they're typing the numbers into an analog entry on Wonderware and stored and processed as real (float) in the PLC. The problem is the nature of how the floats are stored means they're not accurate when you get up to the very large numbers. RSLogix is also rounding the decimals, sometimes to funky numbers.

I've tried using integers, but I can't get the resolution to come in, even through formatting.

I'm sure there has to be a solution to this, and reducing the resolution might be it, but I'd rather keep the resolution if possible.

We have 3 meter with hard mechanical counters on the top that go up to 99,999,999.99 and then roll over to 0. We only use them as a verification/check against our flow computer for the indicated volume.

I'm using Wonderware v10.6 and RSLogix5000.

Currently they're typing the numbers into an analog entry on Wonderware and stored and processed as real (float) in the PLC. The problem is the nature of how the floats are stored means they're not accurate when you get up to the very large numbers. RSLogix is also rounding the decimals, sometimes to funky numbers.

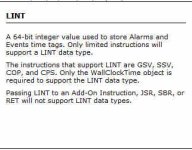

I've tried using integers, but I can't get the resolution to come in, even through formatting.

I'm sure there has to be a solution to this, and reducing the resolution might be it, but I'd rather keep the resolution if possible.