jjnelson81

Member

Well lets try this again. I wrote a long post and my browser crapped out on me.

I am looking to write my own PID equations into my PLCs. I work for an OEM that uses any PLC that is specified. I want to eventually write an auto-tune routine for out process but needed a standard PID loop to get that down. I know everyone is aware that each PLC mfg uses a little bit different form of PID controls. This does not make it easy to have a piece of standard equipment (less the PLC) and use the same logic for auto-tuning the PID. Here are some equations:

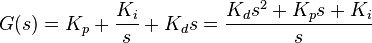

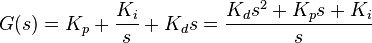

Here are 2 equations, the first being a pretty standard PID equation and the second being the Laplace Transmform form of the same equation. It looked to me that the Laplace form would be easier to implement with the math functions available in a PLC. Here is my stumbling block.

What is the "s" variable in the second equation? I think it is a function of time but don't know how to get it. Do I need to run some timers and sample the error over time?

Any help would be great. I have scouered the internet for the last week reading and learning, I know what each portion of the equation is supposed to do, how do I make my own?

I am looking to write my own PID equations into my PLCs. I work for an OEM that uses any PLC that is specified. I want to eventually write an auto-tune routine for out process but needed a standard PID loop to get that down. I know everyone is aware that each PLC mfg uses a little bit different form of PID controls. This does not make it easy to have a piece of standard equipment (less the PLC) and use the same logic for auto-tuning the PID. Here are some equations:

Here are 2 equations, the first being a pretty standard PID equation and the second being the Laplace Transmform form of the same equation. It looked to me that the Laplace form would be easier to implement with the math functions available in a PLC. Here is my stumbling block.

What is the "s" variable in the second equation? I think it is a function of time but don't know how to get it. Do I need to run some timers and sample the error over time?

Any help would be great. I have scouered the internet for the last week reading and learning, I know what each portion of the equation is supposed to do, how do I make my own?