Whohastimeforthis

Lifetime Supporting Member

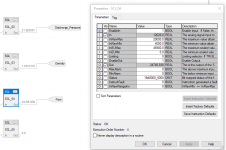

We use Function Block for most all of our scaling, and of course the SCL block for most everything. We also configure the AI in 4-20ma and Engineering Units. It works great but I've noticed going from 1769-IF4 projects to a 1769-IF4I projects, I will find the InRawMax and InRawMin will often be the same on both.

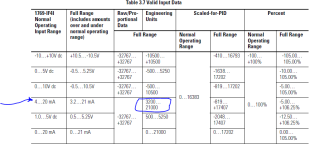

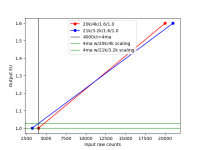

Trying to find out why , I researched (A LOT) to be sure that the RawMin and RawMax for the IF4 should be 4000 and 20000 and NOT 3200 and 21000.

Just to keep it simple, according to the book the 1769-IF4, 4-20ma range and 4-20ma Input Value the Engineering Units should be 4000 to 20000. So far so good. But when I get to the book for the 1769-IF4I, it throws in the "Full Range" and that's where I'm getting confused. It says RawMin and RawMax should be 3200 and 21000.

Here's the question:

Should RawMin and RawMax on the IF4I be 4000 and 20000? Considering the "Full Range" is 3.2-21ma, which is more than the usual 4-20ma.

Or did someone before me fail to update the RawMin and RawMax in the different 1769-IF4(I) cards?

I thought I had it figured out long ago until I found these settings/configs similar and in my research everyone is mentioning "Full Range", or maybe that was just in the 1756-L7X stuff where -32768 to 32767 comes in.

I would so appreciate any help because I can't find this specific of a question ANYWHERE.

Trying to find out why , I researched (A LOT) to be sure that the RawMin and RawMax for the IF4 should be 4000 and 20000 and NOT 3200 and 21000.

Just to keep it simple, according to the book the 1769-IF4, 4-20ma range and 4-20ma Input Value the Engineering Units should be 4000 to 20000. So far so good. But when I get to the book for the 1769-IF4I, it throws in the "Full Range" and that's where I'm getting confused. It says RawMin and RawMax should be 3200 and 21000.

Here's the question:

Should RawMin and RawMax on the IF4I be 4000 and 20000? Considering the "Full Range" is 3.2-21ma, which is more than the usual 4-20ma.

Or did someone before me fail to update the RawMin and RawMax in the different 1769-IF4(I) cards?

I thought I had it figured out long ago until I found these settings/configs similar and in my research everyone is mentioning "Full Range", or maybe that was just in the 1756-L7X stuff where -32768 to 32767 comes in.

I would so appreciate any help because I can't find this specific of a question ANYWHERE.