Anibal Hernandez

Member

- Join Date

- Aug 2003

- Posts

- 71

What is the best way to send 4 signals to a counter?

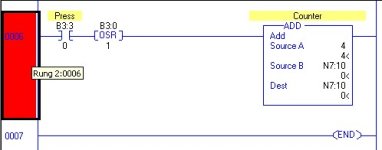

On a Micrologix 1000 I need to show 4 counts on every cycle of the press. That is every time the press comes down and up the counter must be counting by fours.

Assuming Machine is turned ON for the first time and the counter is reset to zero, first machine cycle the counter is 4, the next machine cycle the counter is 8, then another cycle completes and the counter is 12…. So on and so forth.

What is the best way to send 4 signals to this counter? This is a regular counter that increments every time a pulse is received.

Andy

On a Micrologix 1000 I need to show 4 counts on every cycle of the press. That is every time the press comes down and up the counter must be counting by fours.

Assuming Machine is turned ON for the first time and the counter is reset to zero, first machine cycle the counter is 4, the next machine cycle the counter is 8, then another cycle completes and the counter is 12…. So on and so forth.

What is the best way to send 4 signals to this counter? This is a regular counter that increments every time a pulse is received.

Andy