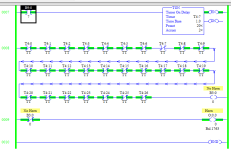

Compactlogix controller, program has 28 conveyors that use TON's to start the conveyors. The TT sounds a warning horn during start and the DN starts the motor. The ladder line with the horn OTE has 32 (28 conveyors plus HMI and physical) XIC's on parallel rungs. Is there a cleaner way to do the same thing? Would alias tags be a better option?

Thanks.

Thanks.