gmarowski

Member

I ran across the following lines of code and I had a couple of questions. Keep in mind I'm fairly new and trying to understand the hows and why's of messaging. Here's the two rungs in question

See attached jpg:

My first question is: Wouldn't it be more appropriate to put the N14:0/13 branch around the N14:0/12 instruction then unlatch the message and start again?

Second: Why use the message bits at all? other then for error tracking, and to make sure the same message doesn't get sent repeatedly?

Thanks for the help in advance.

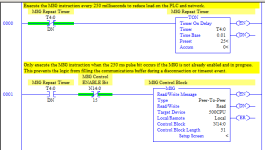

See attached jpg:

My first question is: Wouldn't it be more appropriate to put the N14:0/13 branch around the N14:0/12 instruction then unlatch the message and start again?

Second: Why use the message bits at all? other then for error tracking, and to make sure the same message doesn't get sent repeatedly?

Thanks for the help in advance.