Is it safe to "cut" a 4-20mA line with a relay contact?

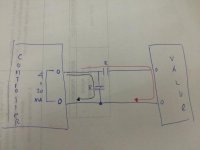

I have connected a motorized valve on a temperature controller. The valve moves proportionately with the temperature from the controller. However, on some cases, I would like to totally close the valve regardless of the temperature reading. I would think cutting the 4-20mA line may do it.

Thanks

I have connected a motorized valve on a temperature controller. The valve moves proportionately with the temperature from the controller. However, on some cases, I would like to totally close the valve regardless of the temperature reading. I would think cutting the 4-20mA line may do it.

Thanks