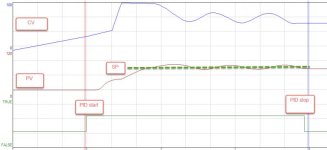

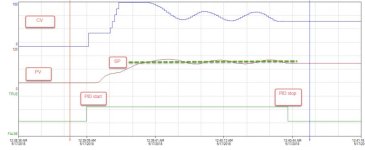

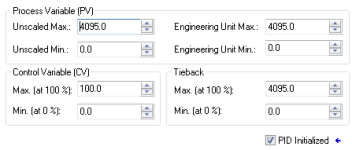

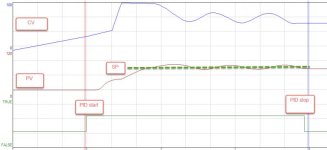

I am troubleshooting a PID loop developed and tuned by others. It is a heat exchange process, utilizing steam and control valve to heat up process water from 0 to 80 degree in 1.5 minutes. PID equation is independent and current Kp value is 25, Ki value is 10 andn Kd is 0. See attachment for trend of PV and CV. CV open from 0 to 100% and PV obviously go into oscillation status.

What procedure shall I follow to identify right Kp and Ki value and allow temperature to reach SP fast(in 1.5 minutes) and without overshoot?

Thanks very much for your help!

What procedure shall I follow to identify right Kp and Ki value and allow temperature to reach SP fast(in 1.5 minutes) and without overshoot?

Thanks very much for your help!