siopaoAsado

Member

Hi all,

I just recently started working with Unity Pro XL and i can say that i am not still used to it. I am at ease working with siemens PLCs but now i am having trouble with unity.

Here's my problem:

I created an instance DDT (structured variable) which comprises of REALs and BOOLs. However, i dont know how to correctly input the addresses.. Whenever i try to put a %MW to the base tag, the BOOLs also take up the MW address.

How can i correctly address each variable in my DDT?

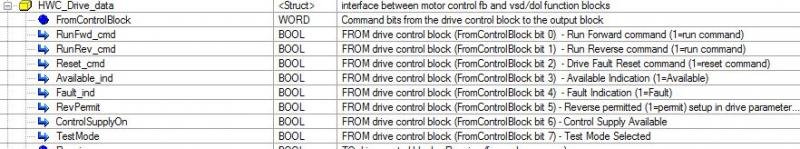

I attached the screenshots for everyone's reference..

I hope someone will help me with this..

Thanks.

I just recently started working with Unity Pro XL and i can say that i am not still used to it. I am at ease working with siemens PLCs but now i am having trouble with unity.

Here's my problem:

I created an instance DDT (structured variable) which comprises of REALs and BOOLs. However, i dont know how to correctly input the addresses.. Whenever i try to put a %MW to the base tag, the BOOLs also take up the MW address.

How can i correctly address each variable in my DDT?

I attached the screenshots for everyone's reference..

I hope someone will help me with this..

Thanks.